Composite Cables

Recognising the ever-increasing needs of the discerning user, the company has invested heavily in the expansion of its Plastics Extrusion Department so that it can now offer an extrusion service on a range of cables from 0.25mm to 90mm diameter. Extrusion may take the form of impregnantion or complete coating, or both, and can be effected through the use of various materials - PVC, nylon, polypropylene, polyethylene, urethane, etc. The plant is capable of extrusions on core materials other than steel wire rope and strand-synthetic fibres, copper, aluminium, in fact, virtually anything which can be received in coils or on reels.

NORSELAY

|

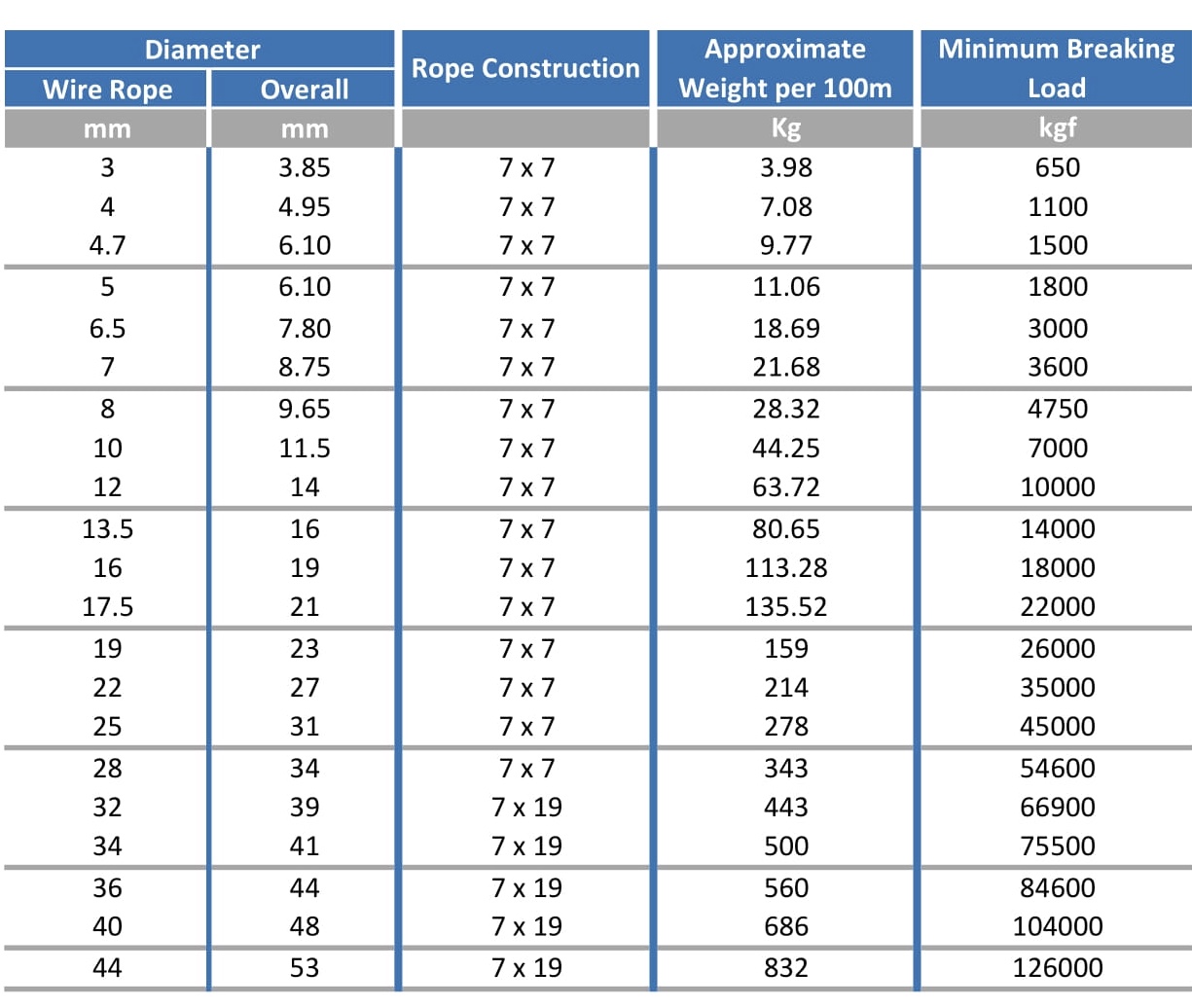

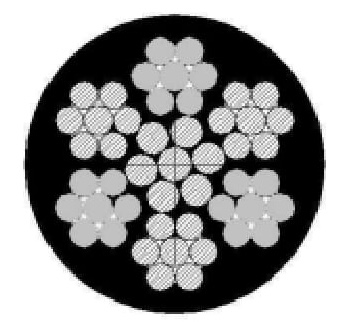

'Norselay' is a composite solid section of 'herringbone' construction, either 7x7 or 7x19 galvanised high tensile carbon steel wire rope and black ultra-violet inhibited polypropylene. The 'herringbone' construction has long been known to the wire rope industry and the effect of the oppositehelix of the wires in the adjacent strands creates channels of space through to the inside of the rope enabling the polypropylene to impregnate deeply between the strands. This produces a strong web of polypropylene locking the covering through the interstices of the rope. This feature prevents the covering from stripping off the rope in the event of damage. It also prevents capillary action and creep-corrosion from water entering the rope if damage to the covering penetrates through to the wires. 'Norselay' has been in use for many years as stays supporting radio antenna towers in tropical marine conditions, such as the Arabian Gulf, and was chosen to give an expected life in excess of stainless steel and other materials. It has been used by BBC, Cable & Wireless, Decca, Marconi, MOD etc. When used as yacht rigging it can also be insulated to provide an excellent aerial for transmitting and receiving. |

Main Advantage of Norselay

|

'Norselay' is impregnated with a waterproof plastic that effectively withstands abrasion and corrosive treatment. It is highly restistant to acids, alkalies, and salts. Each individual strand in 'Norselay' is protected by a controlled thickness of plastic. There is no friction between the strands as the rope bends and flexes in use; thus the internal wear, found in other ropes is eliminated. As the cross-section of 'Norselay' is a dense mixture of wire and plastic, it is impossible for dirt or corrosive elements to enter or travel along the line should the outer plastic coating be cut or abraded. |

|

'Norselay' never needs external greasing thereby considerably reducing maintenance costs.

'Norselay' marine ropes are unaffected by great depths of water. 'Norselay' mast stays resist icing because they do not absorb water through the dense wall plastic coating.