- Home

- Products

- Oil & Energy

- Offshore Wind

- Mooring & Anchoring

- Cranes & Industrial

- Mining & Quarrying

- Fishing

- Elevator

- Grapnel

- Coated Wire Products

- Services

- Downloads

- Group

- FAQ

- News

- Contact Us

|

The ELSTAR 8FS range offers:

|

|

|

The ELSTAR 8SS range offers:

|

|

The ELSTAR 8SF range offers:

|

|

The ELSTAR 8SM range offers:

|

|

The ELSTAR 9SS range offers:

|

|

|

The ELSTAR 8G range offers:

|

|

|

|

|

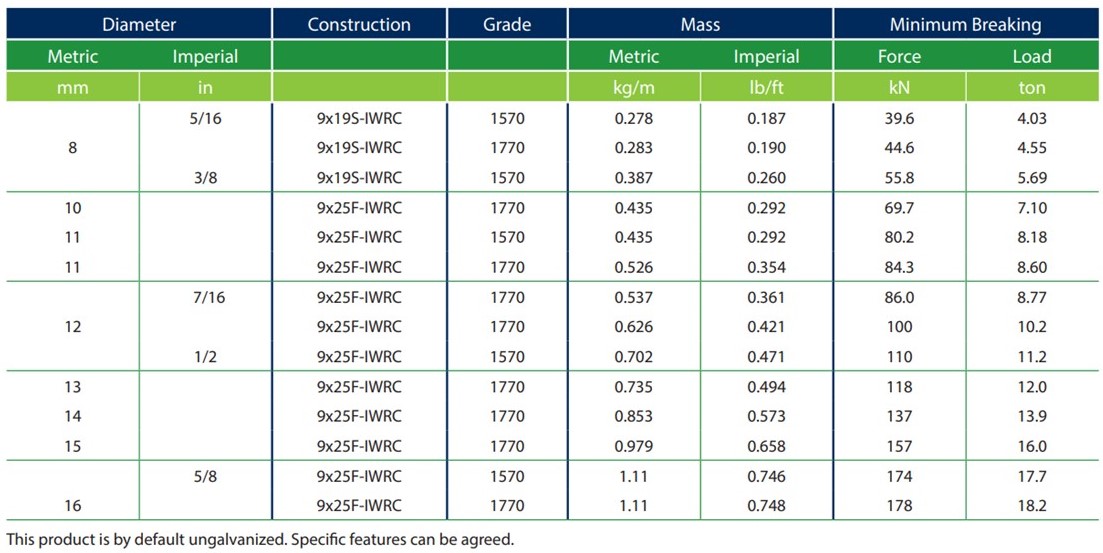

The ELSTAR 6C range offers:

|

|

|

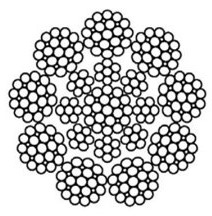

The ELSTAR 9SP range offers:

|

|

|

The ELSTAR 9SS range offers:

|

|

|

The ELSTAR 8WM range offers:

|

|

|

The ELSTAR 8WS range offers:

|

|

|

The ELSTAR 8WF range offers:

|

|

GOVERNOR ROPES

The ELSTAR 6G range offers:

|

|

|

The ELSTAR 6SF range offers:

|

|

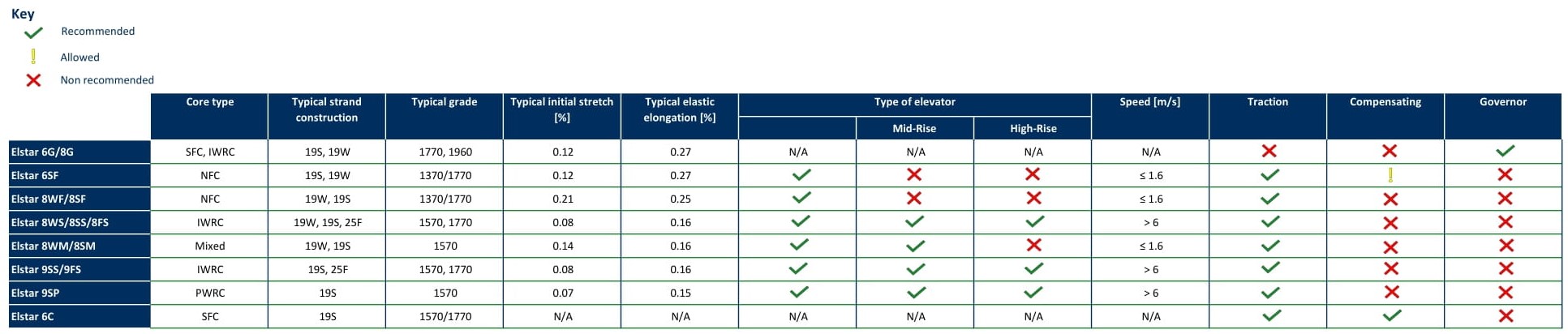

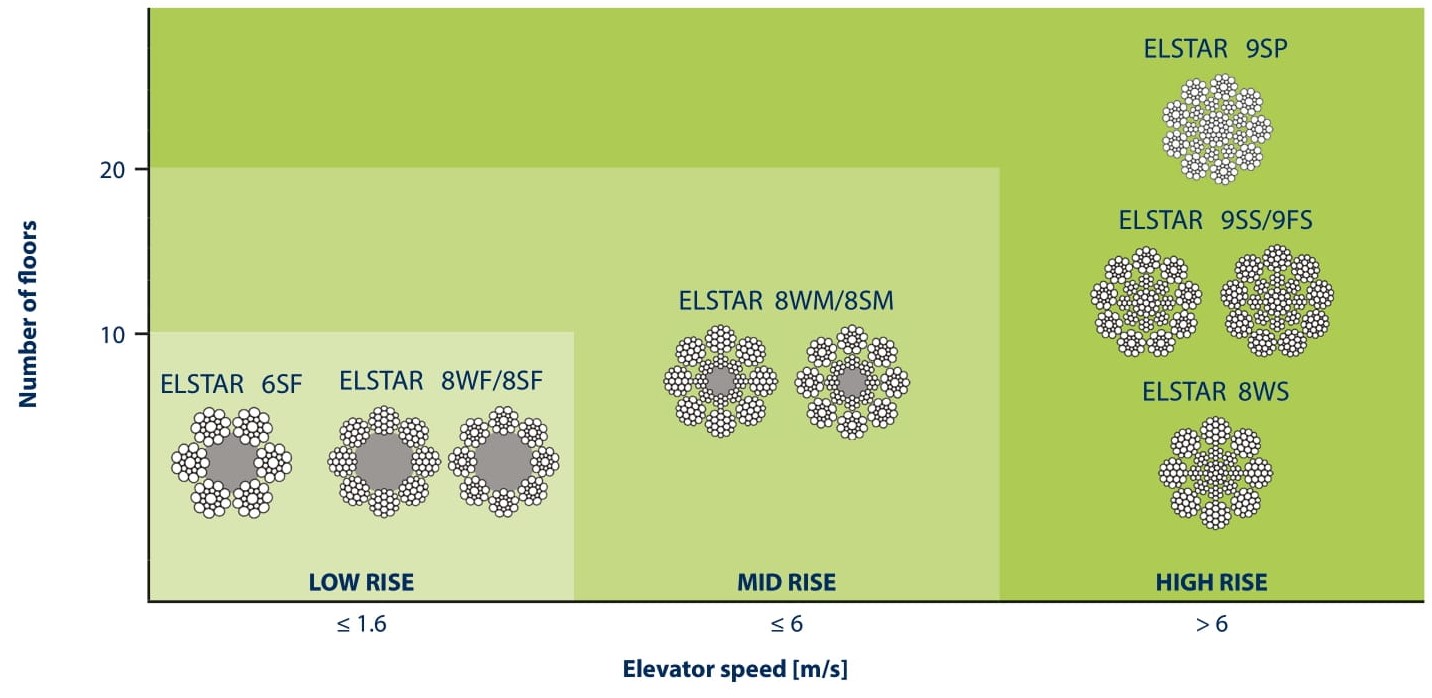

Brunton Shaw UK is a successful manufacturer of high quality, high performance wire ropes which are designed to satisfy the technically demanding requirements of the Elevator Industry.

Brunton Shaw UK is a successful manufacturer of high quality, high performance wire ropes which are designed to satisfy the technically demanding requirements of the Elevator Industry.

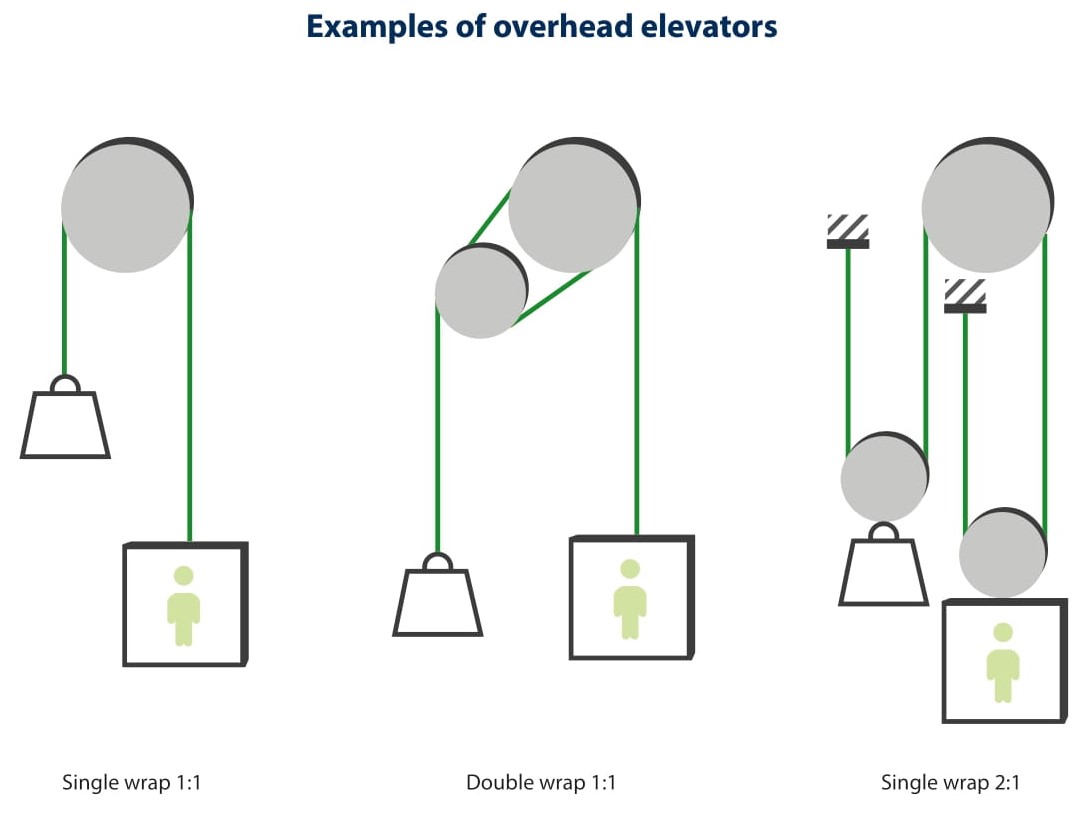

Our Elevator ropes are manufactured in accordance with BS EN ISO 12385:Part 5 ‘Stranded ropes for lifts’ and ISO 4344 ‘Steel wire rope for lifts’, they are suitable for suspension duty on traction drive and roped hydraulic lifts and also for compensating and governor duties.

Brunton Shaw UK is registered to the International quality standard ISO 9001 and is an Approved Supplier to a leading Elevator manufacturer. Brunton Shaw UK apply strict standards of control to all elements of production from material selection to final testing. Elevator rope diameter tolerances need to be less than other types of ropes in order to ensure correct contact between the rope and groove. Throughout the entire production process Brunton Shaw UK ropes are closely monitored to ensure the tolerances are met and the diameter is consistent. Routine and regular testing of rope samples from manufacturing runs for fatigue endurance, elongation characteristics and diameter stability is carried out on a dedicated fatigue test facility to ensure consistent rope performance.