- Home

- Products

- Oil & Energy

- Offshore Wind

- Mooring & Anchoring

- Cranes & Industrial

- Mining & Quarrying

- Fishing

- Elevator

- Grapnel

- Coated Wire Products

- Services

- Downloads

- Group

- FAQ

- News

- Contact Us

|

The WINDMAX range of steel wire ropes offers:

|

|

|

The WINDMAX range of steel wire ropes offers:

|

|

|

The WINDMAX steel wire rope range offers:

|

|

Our range of WINDMAX high strength steel wire ropes are the innovative solution for the renewables and offshore wind markets.

These ropes are designed and manufactured in close concurrence with our customer base and with a green footprint aiming to further reduce the environmental impact during usage.

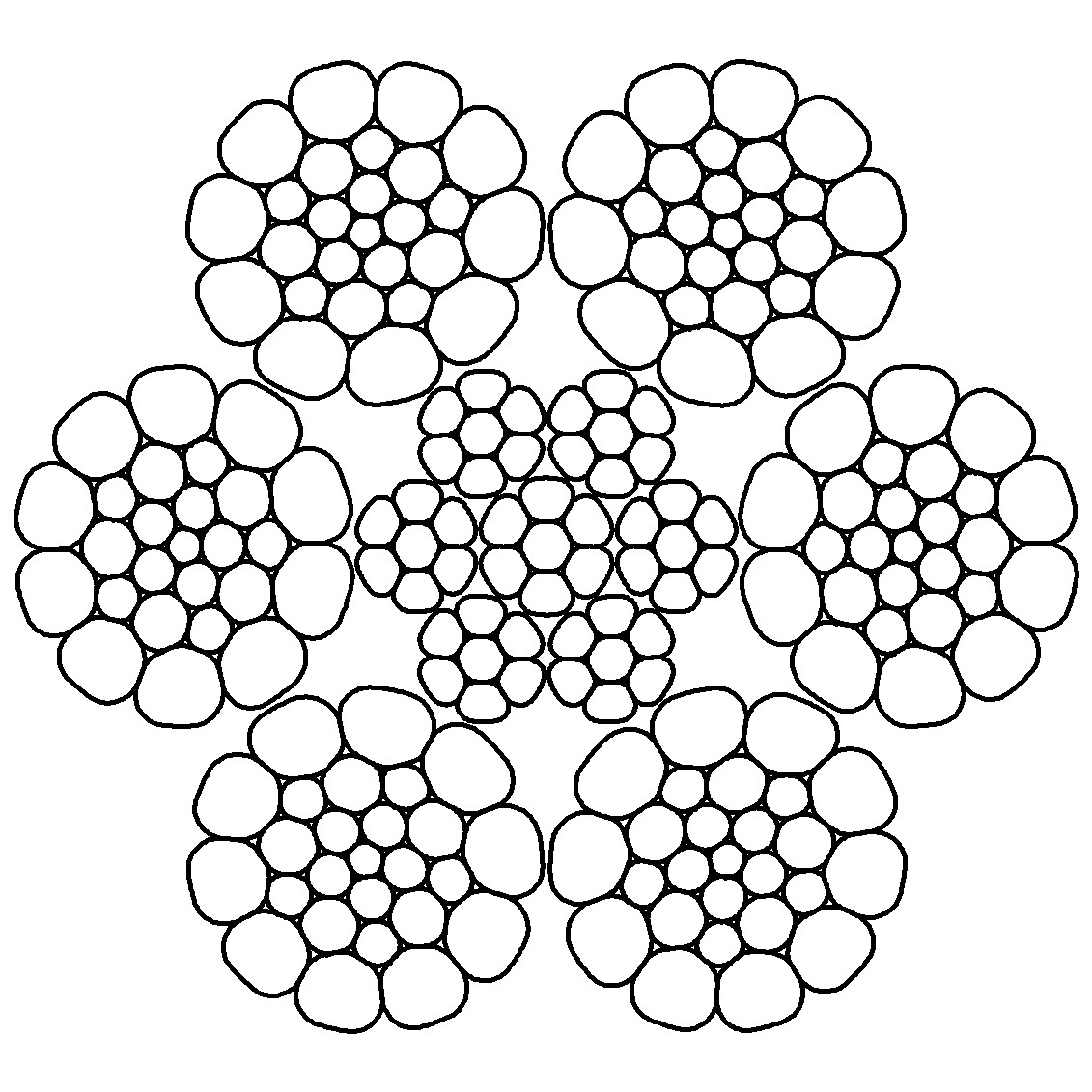

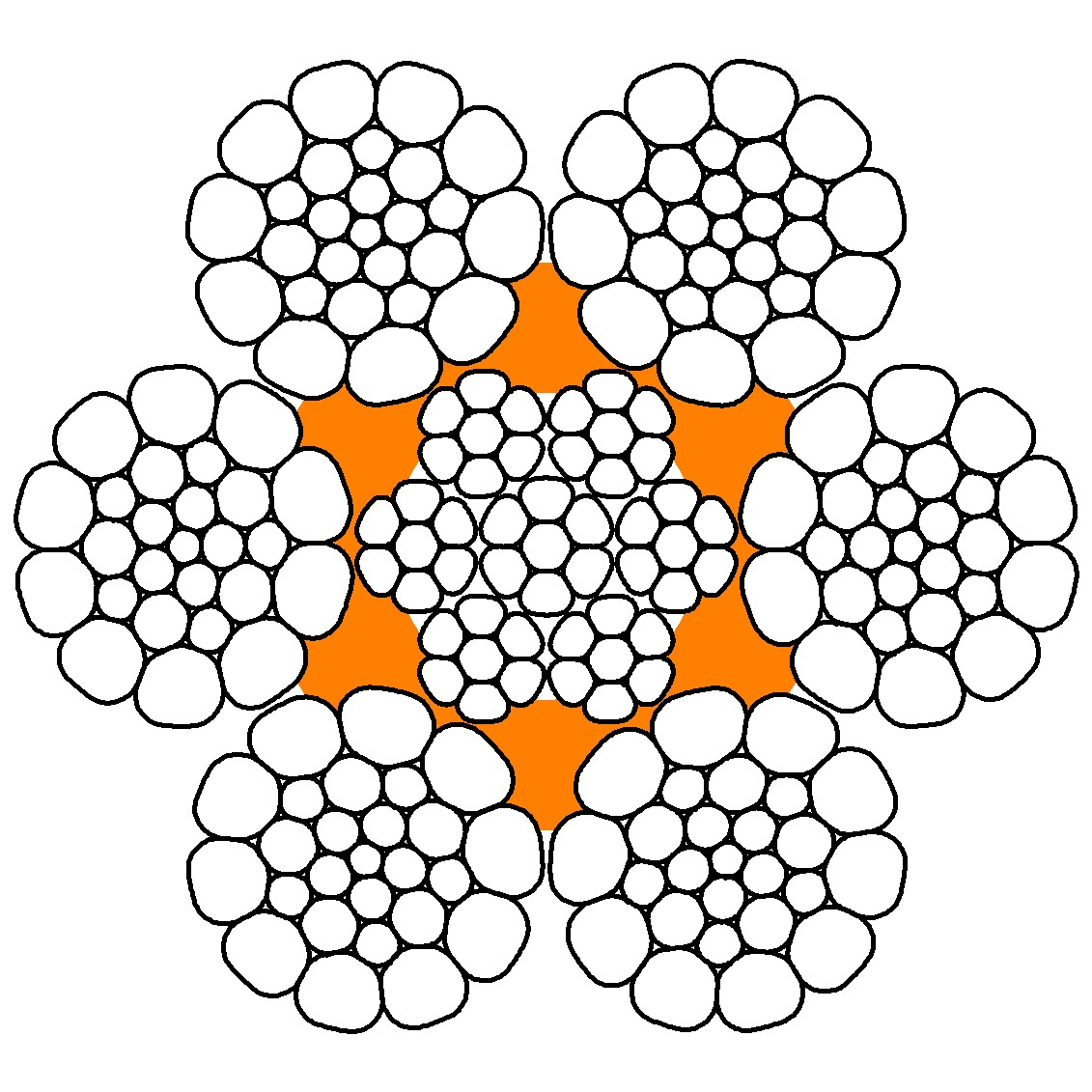

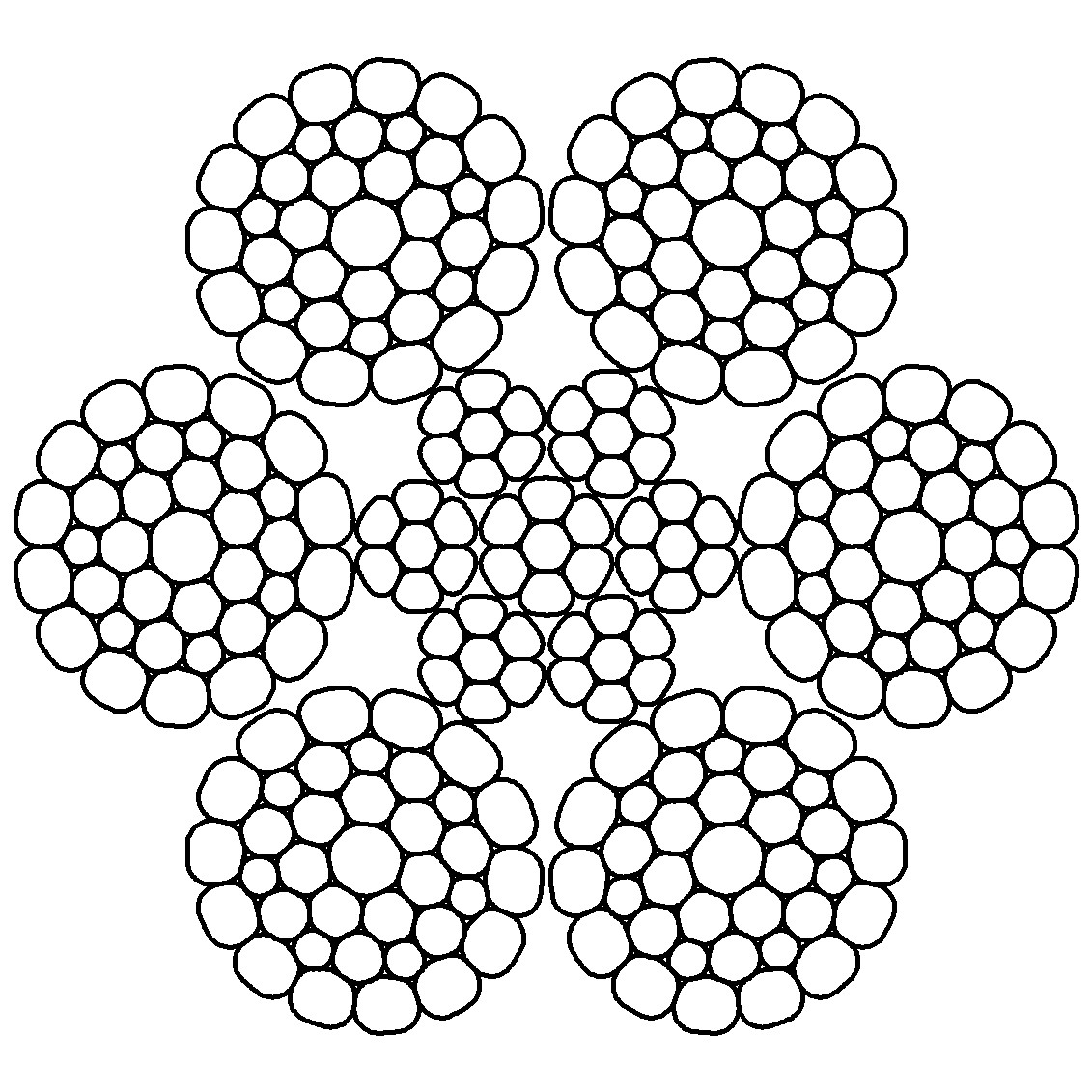

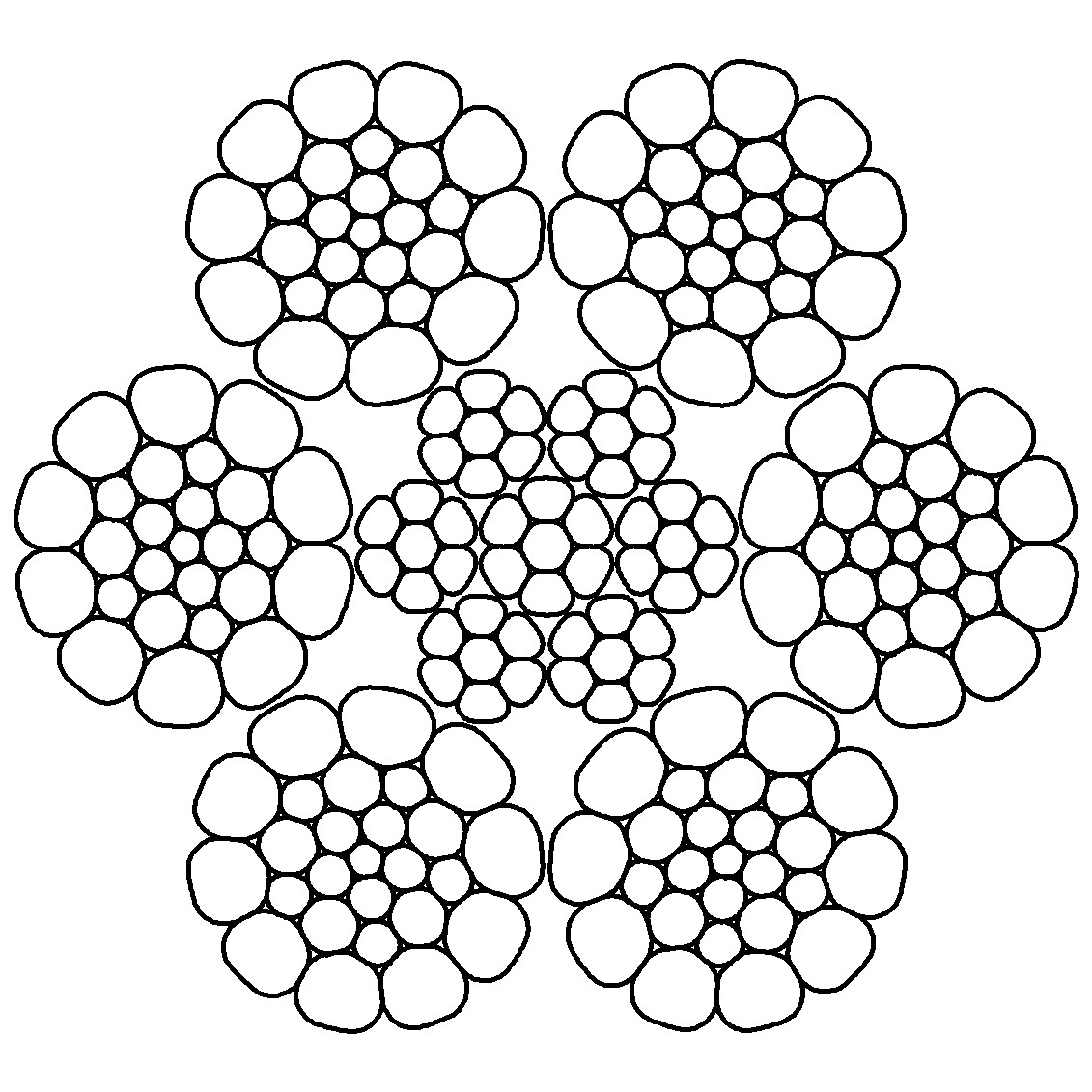

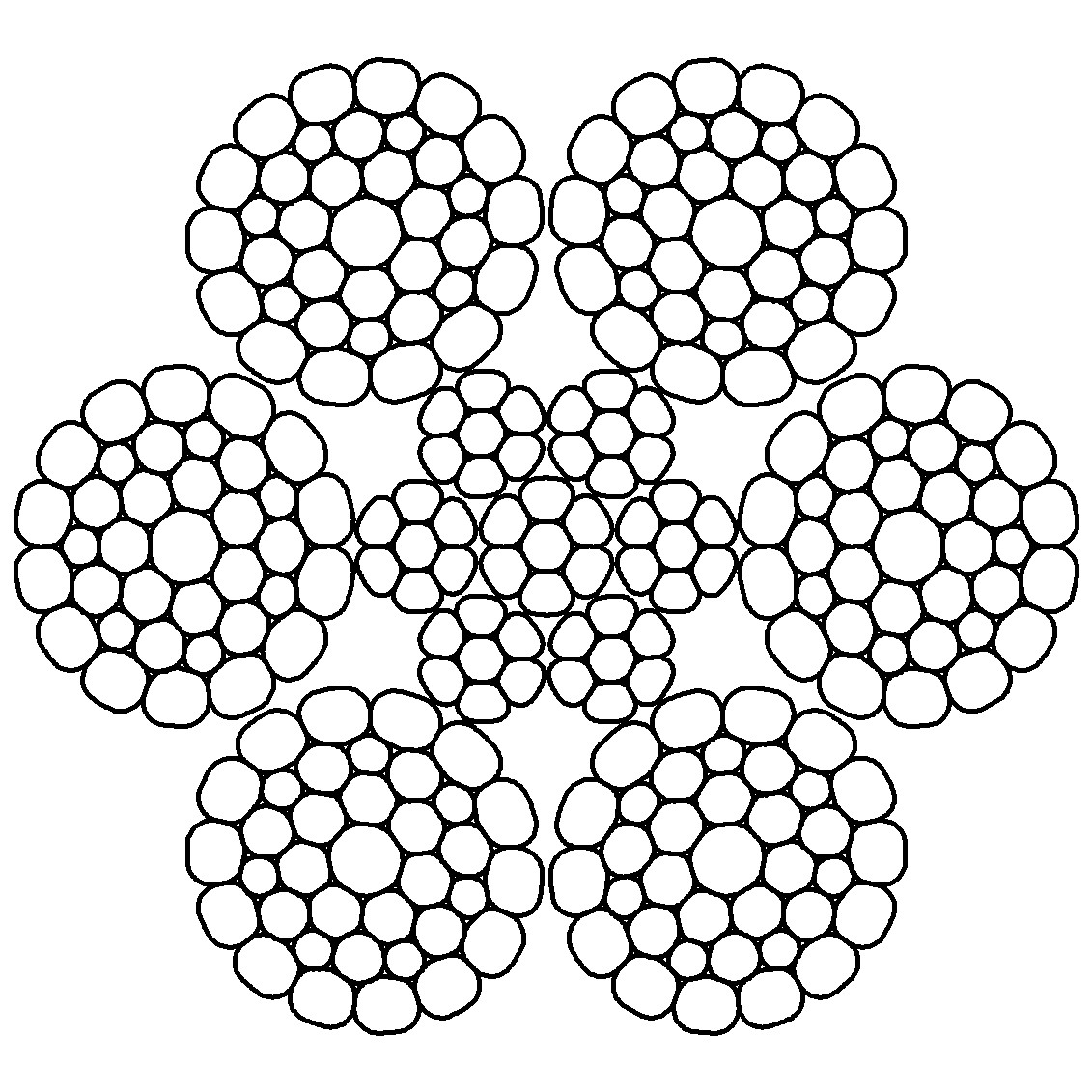

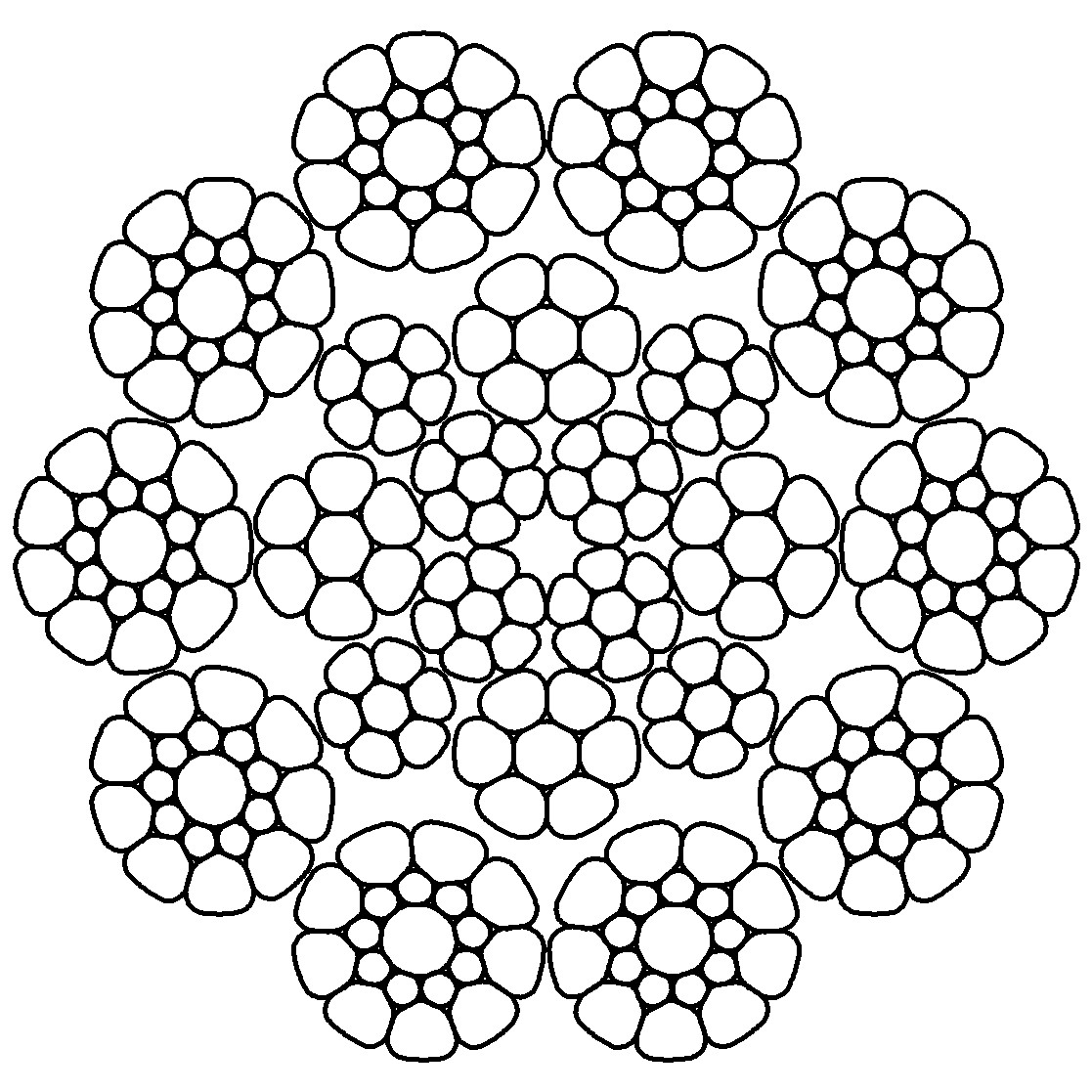

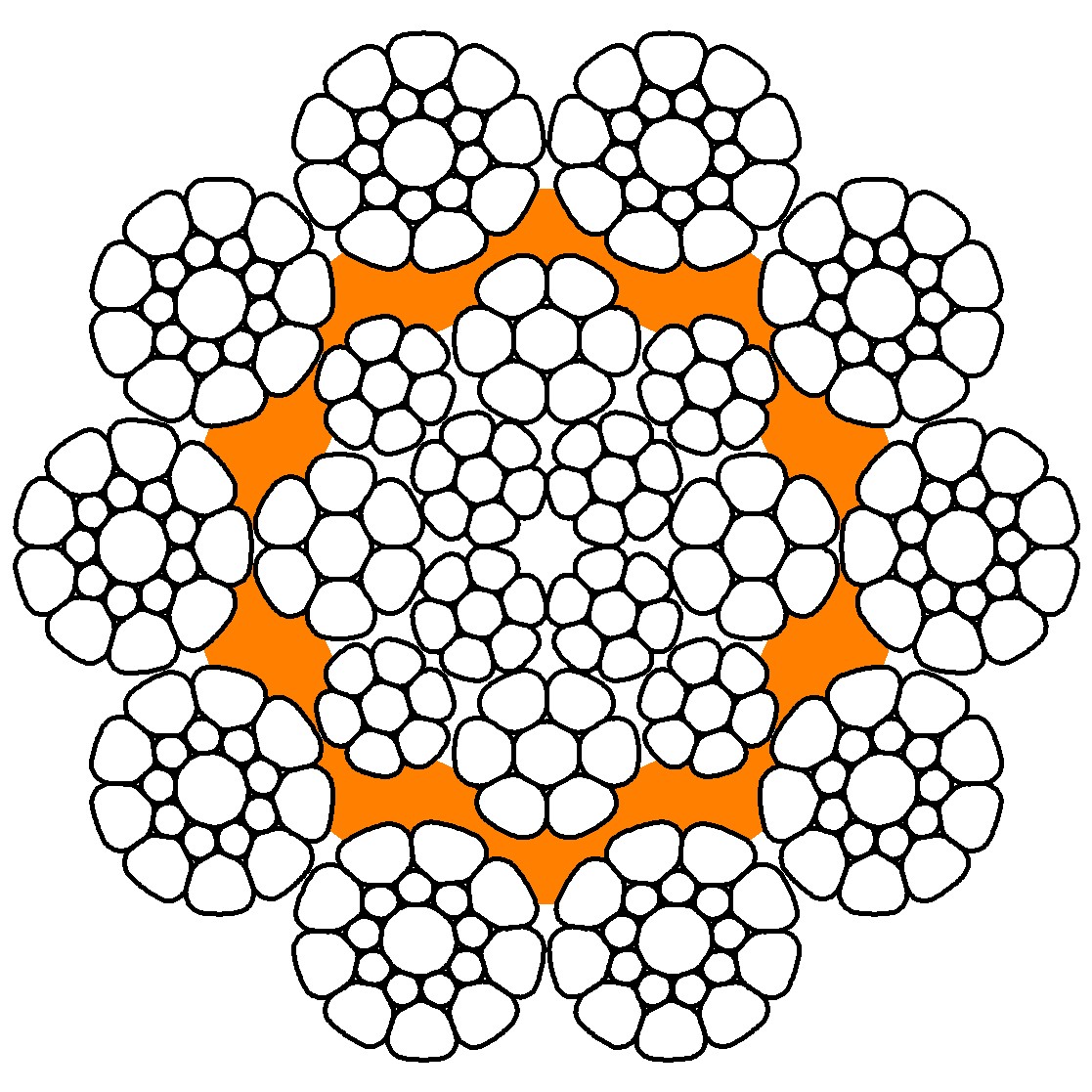

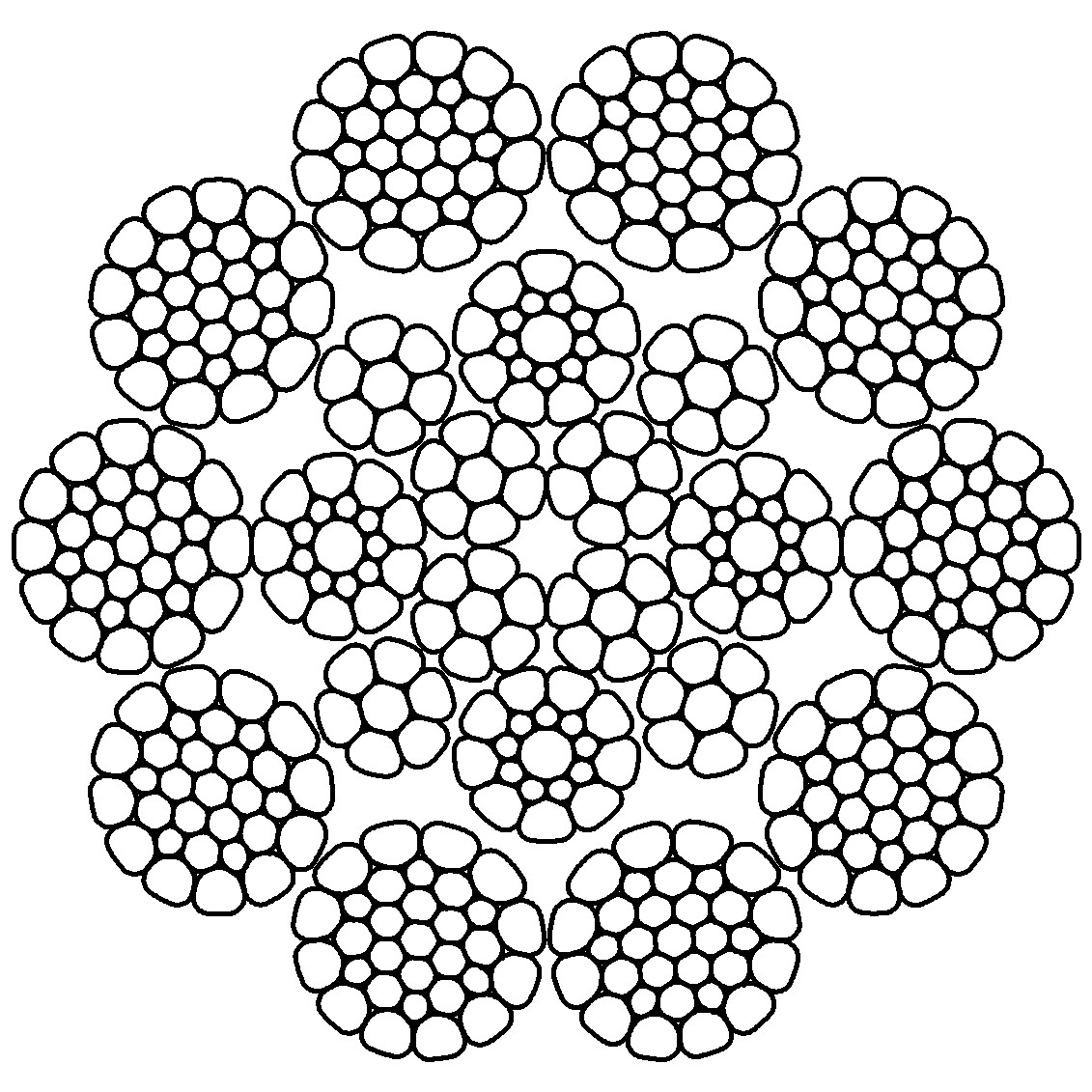

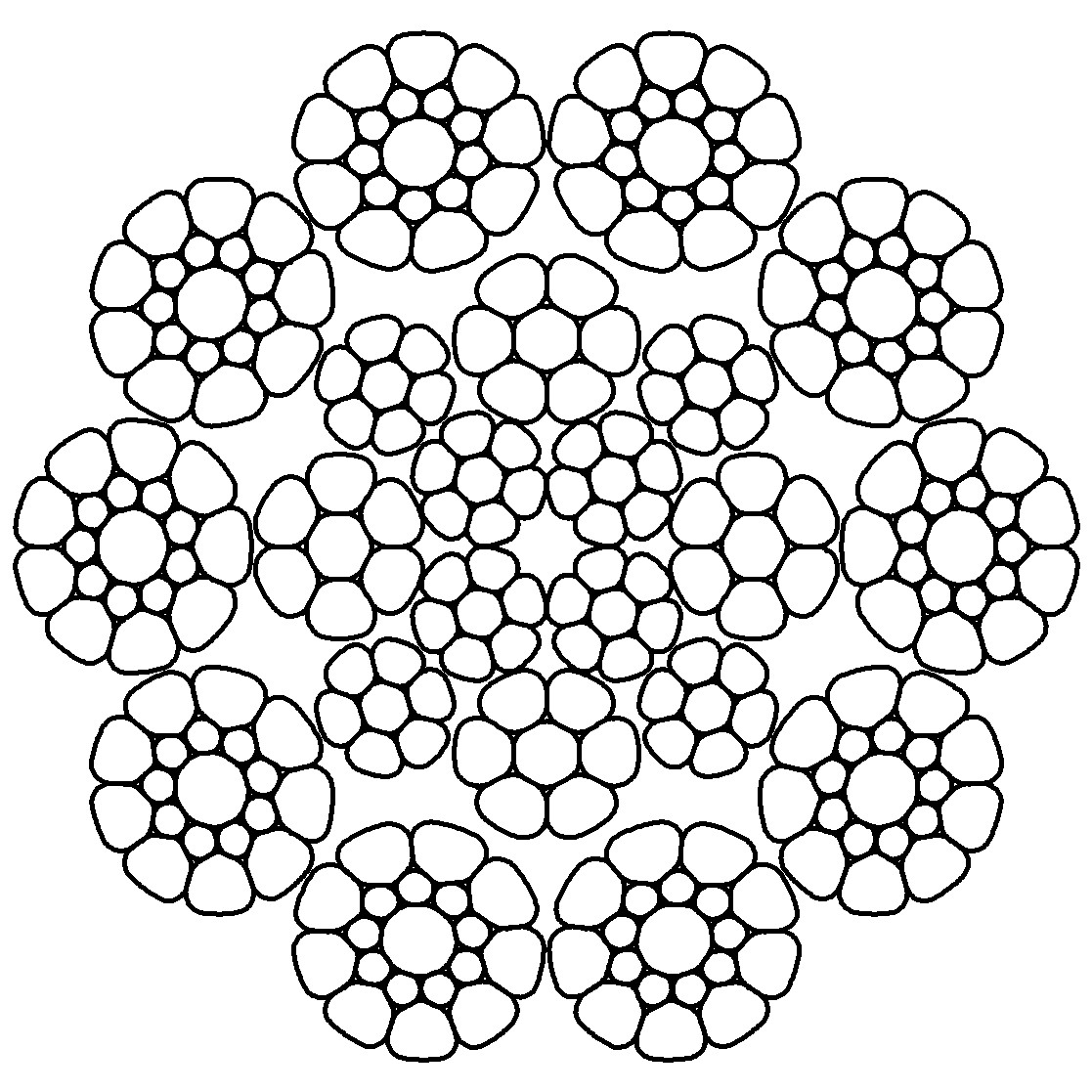

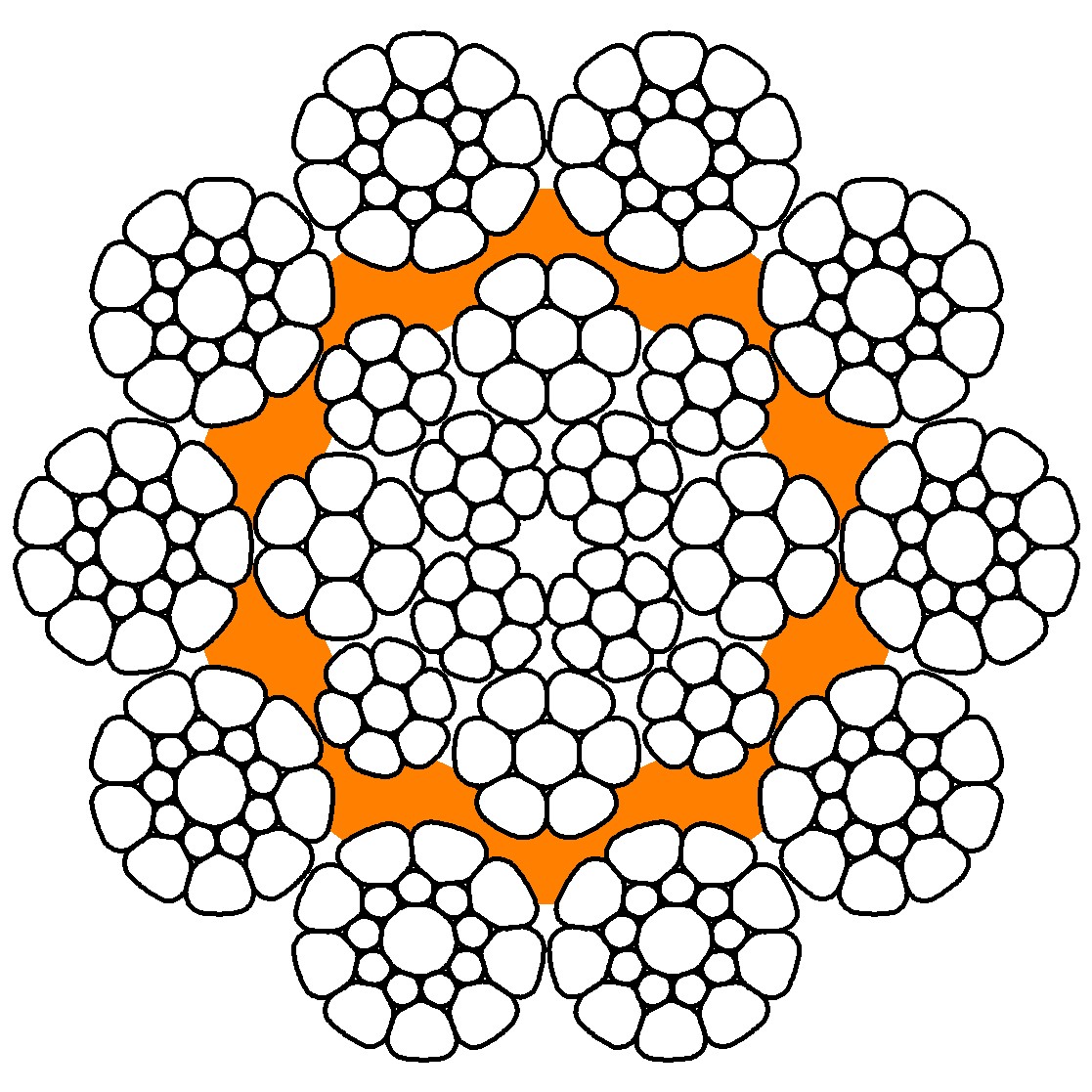

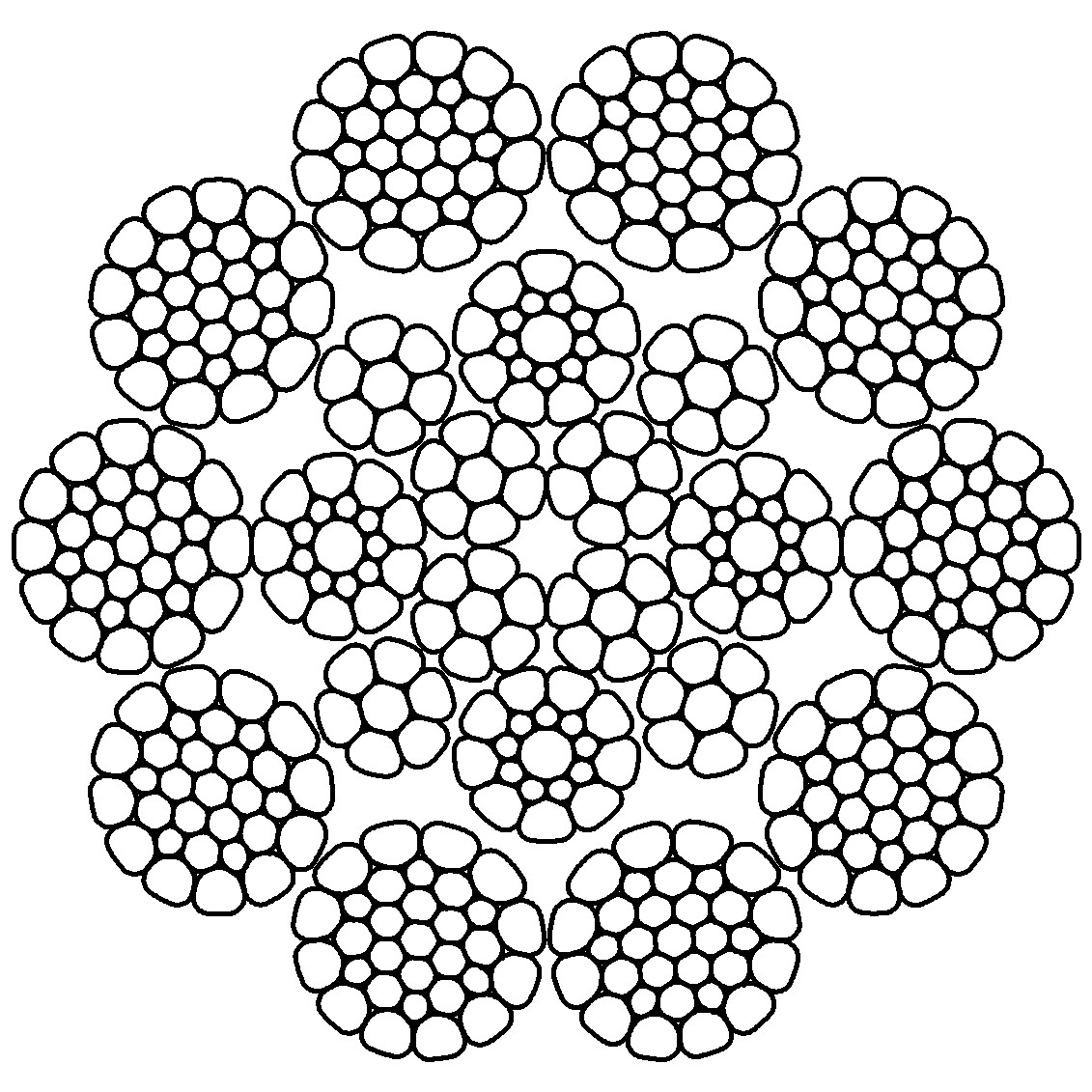

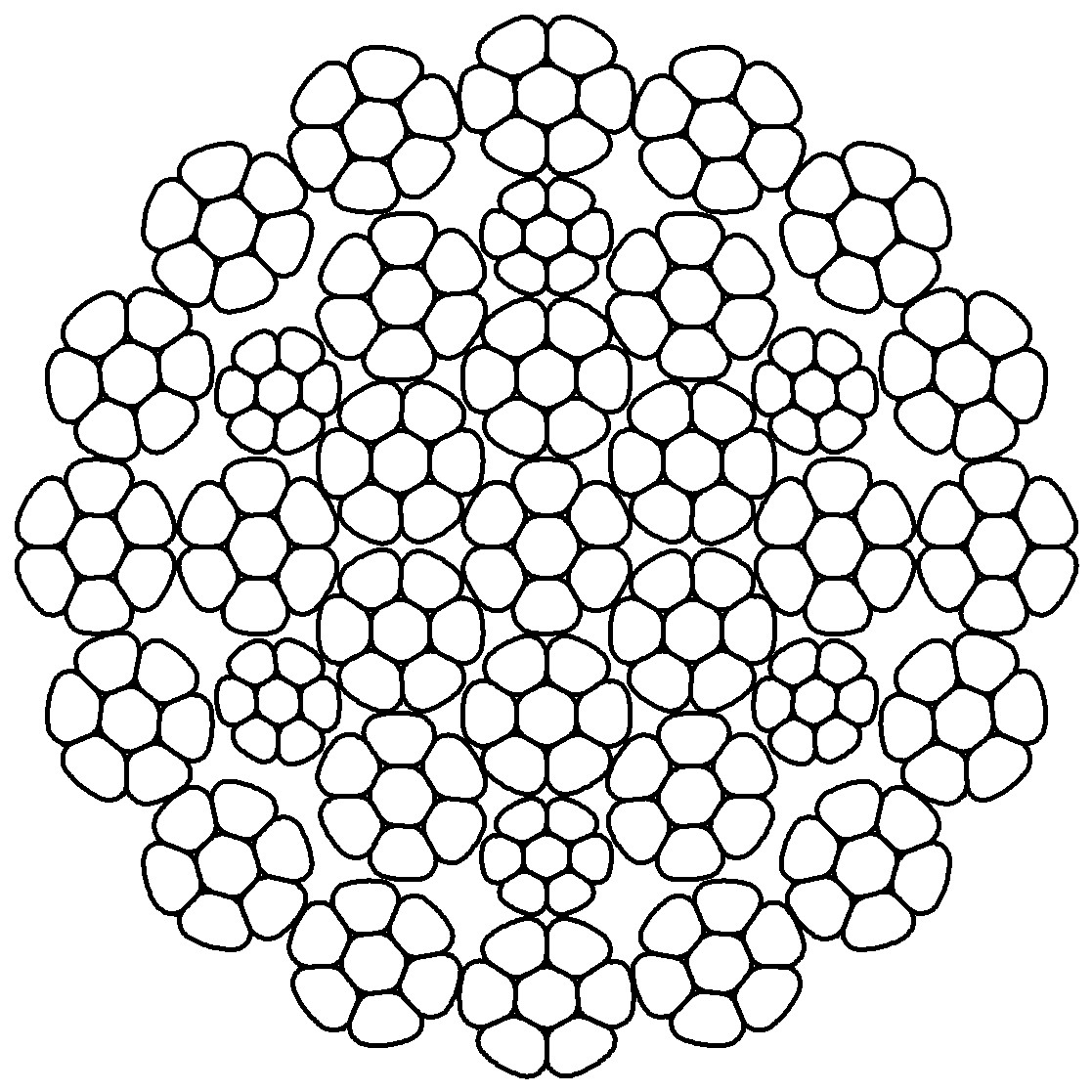

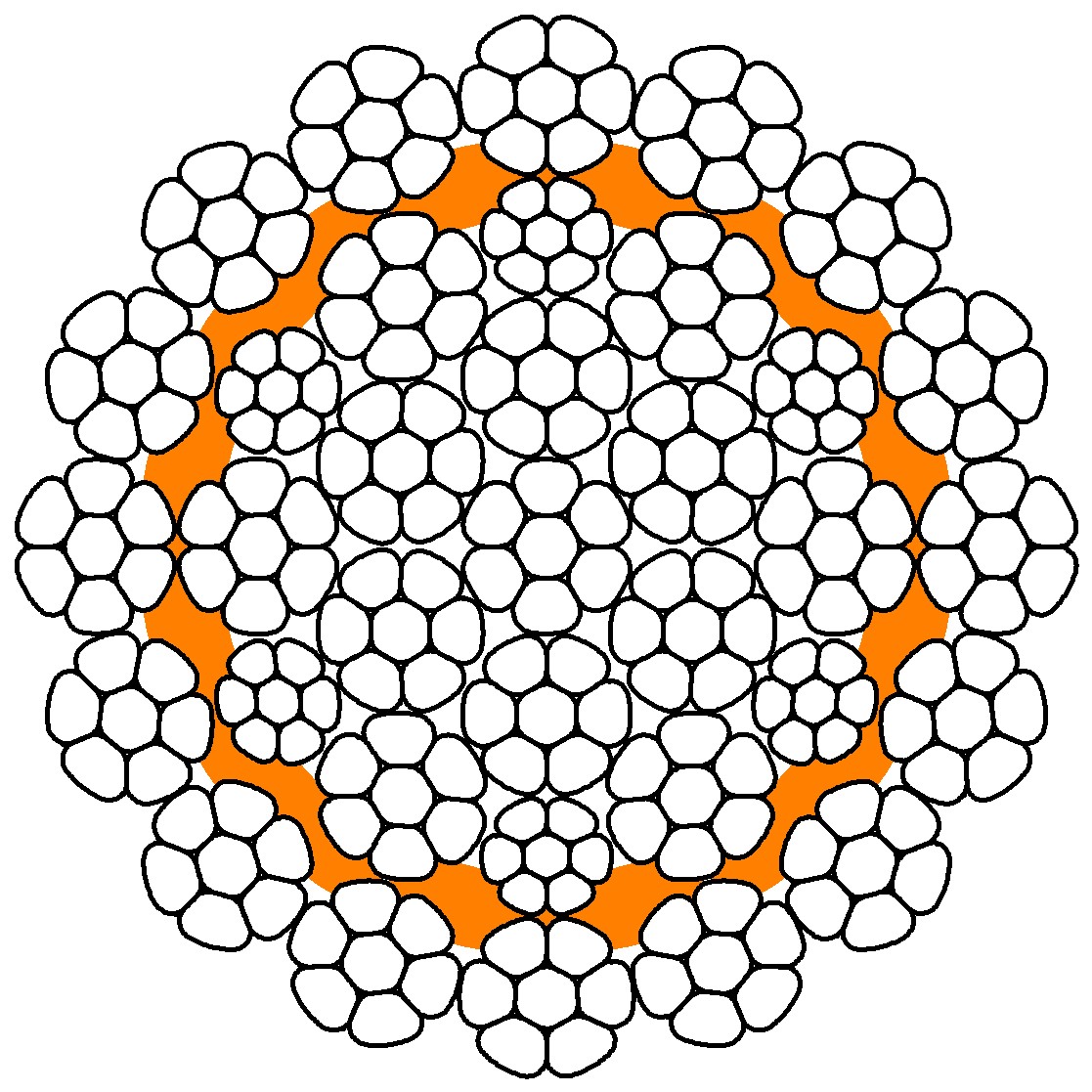

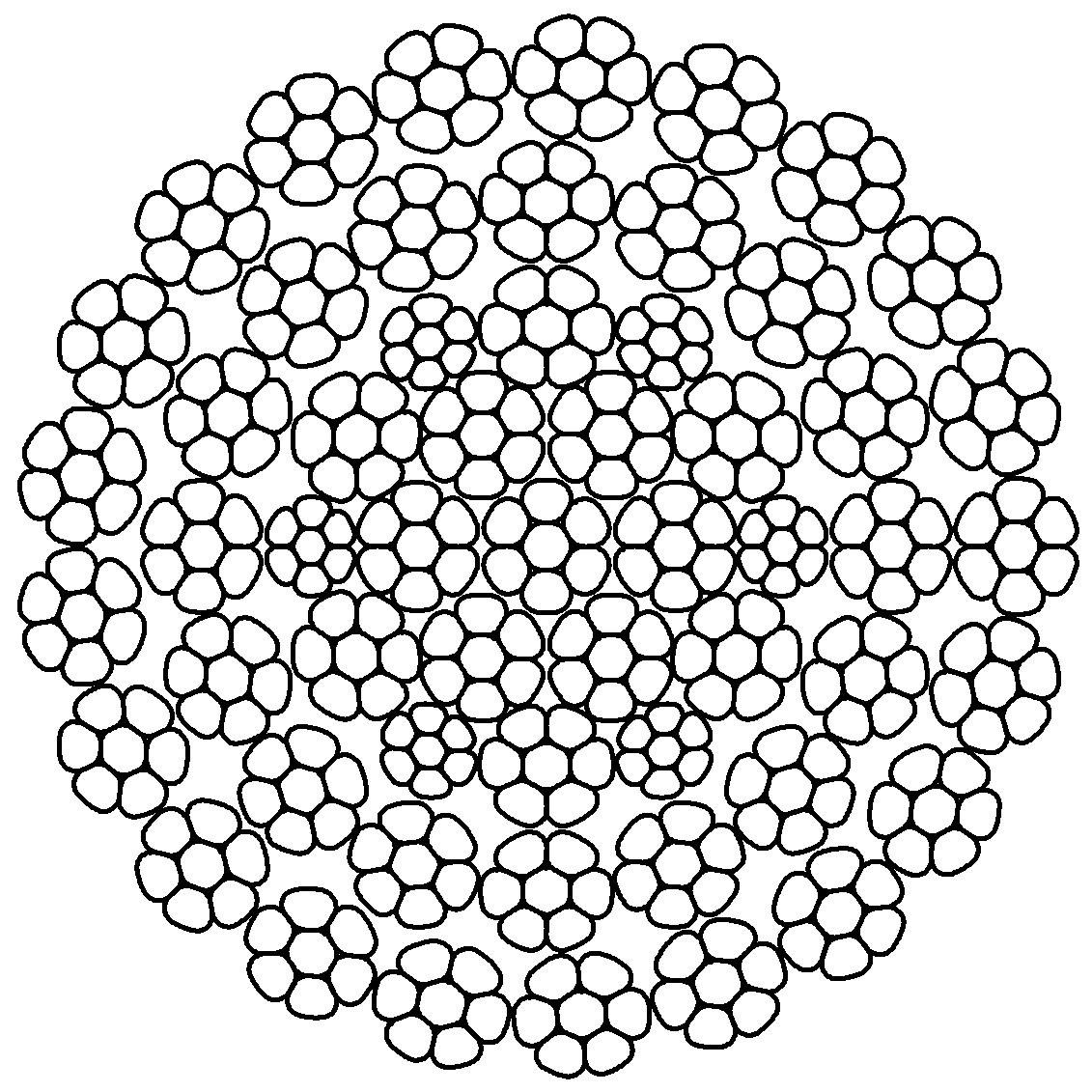

Our WINDMAX wire ropes are available in various constructions, destined for the application at hand. Our non-rotational constructions focus on optimized stability through enhanced rotational properties. Our range of multistrand ropes are designed for ultimate endurance, even under the hardest circumstances.

All our ropes are composed by low tensile, heavily compacted strands, which have proven to be superior in terms of crushing resistance and spooling capability.

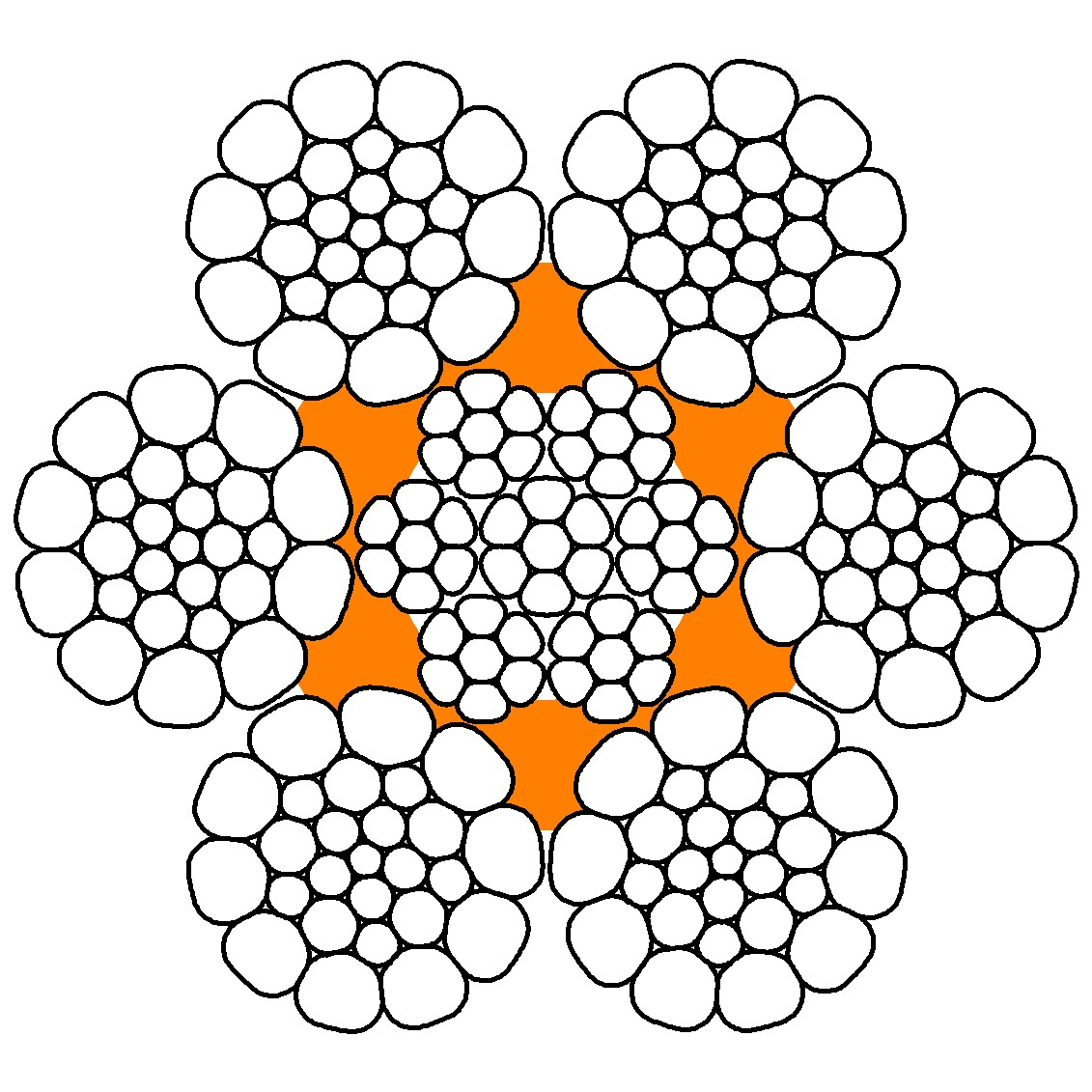

Our range of WINDMAX wire ropes can be lubricated with EAL grease or VGP grease, both being environmentally friendly and compatible with other products for re-lubrication purposes.

A unique feature within our complete range of WINDMAX wire ropes is our lubrication retention system, specifically developed for the purpose of environmental protection. This system provides an extra barrier against lubricant bleeding and wash out. On demand, the lubricant media can be differentiated in order to have an internal core compound and an external "anti-grip" effect.

|

The OCEANMAX 6RT (Riser Tensioner) offers:

|

Drilling Lines

|

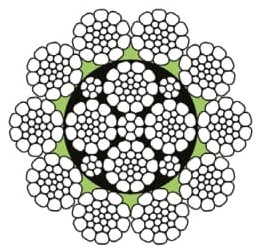

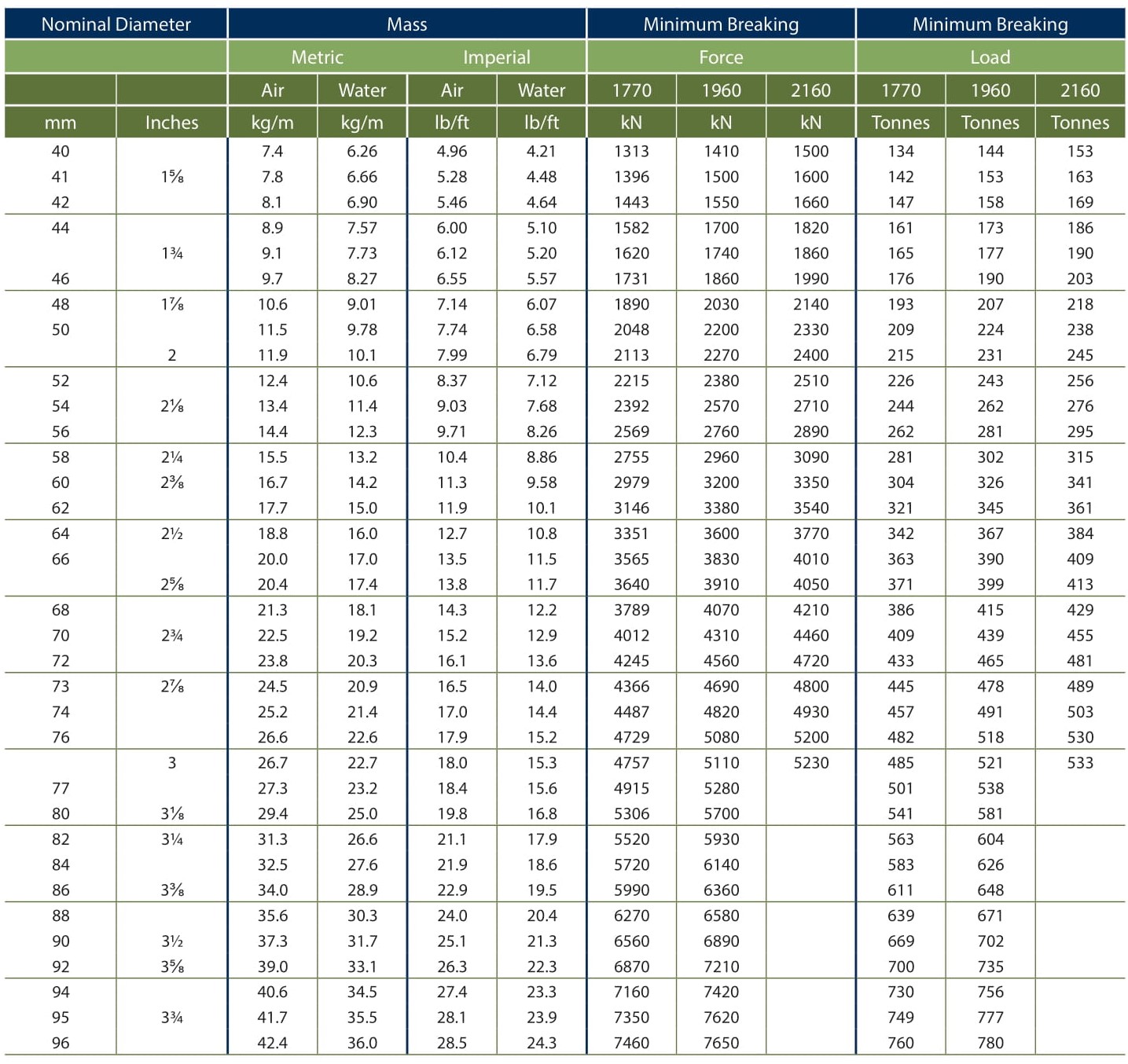

The OCEANMAX 6 offers:

|

|

|

The OCEANMAX 6 offers:

|

|

|

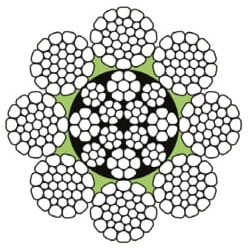

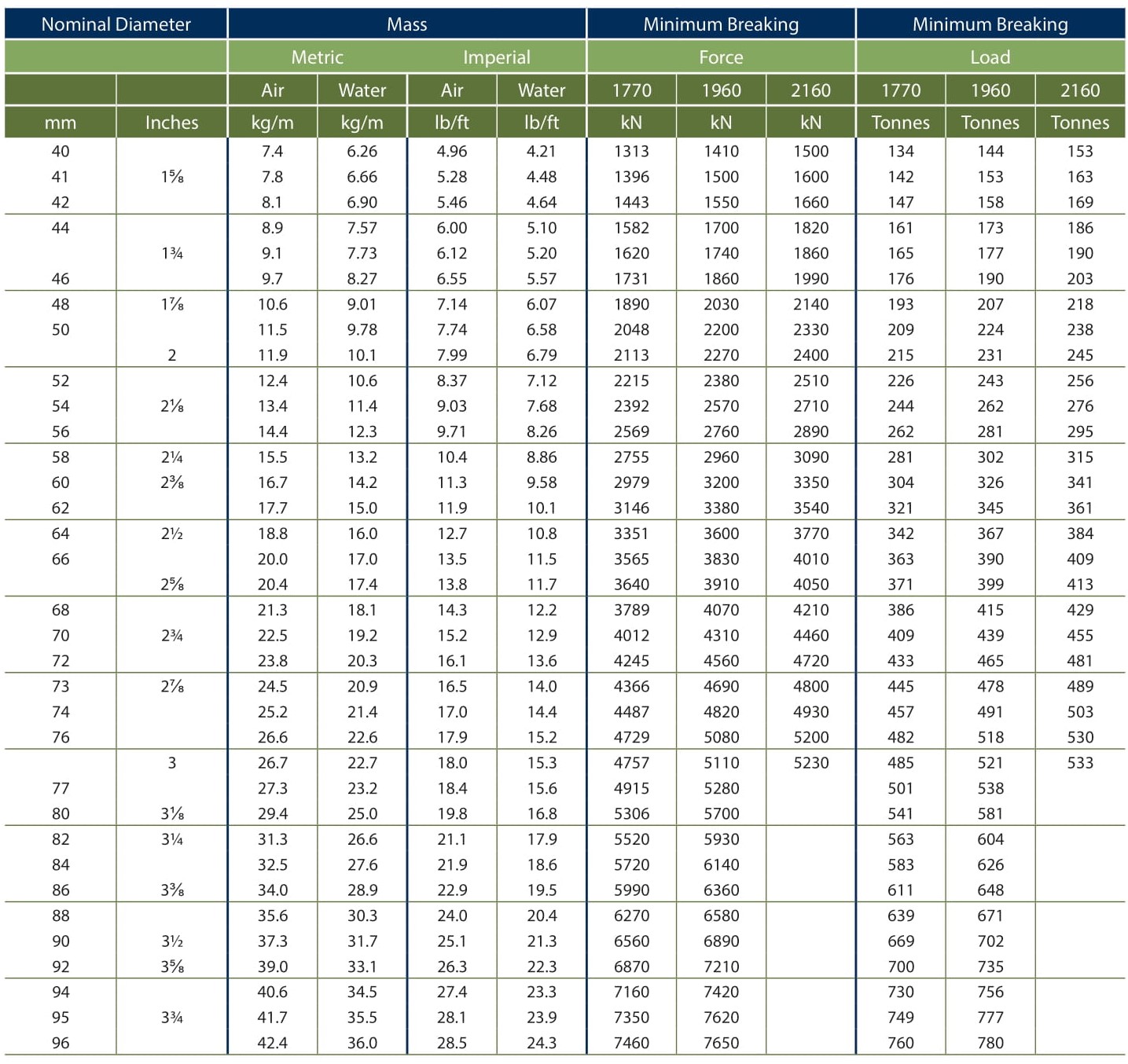

The OCEANMAX 8 offers:

|

|

|

The OCEANMAX 8 offers:

|

|

The OCEANMAX 10 offers:

|

|

|

The OCEANMAX 10 offers:

|

|

|

The OCEANMAX 10S offers:

|

|

With decades of experience in designing, manufacturing and supplying high strength steel wire ropes, Brunton Shaw has developed a range of specialist steel wire ropes for the Oil & Energy Industry.

These ropes are designed and manufactured to the very strict technical specifications demanded by our customers for today's challenging conditions.

The OCEANMAX 35 offers:

|

|

|

The OCEANMAX 35 offers:

|

|

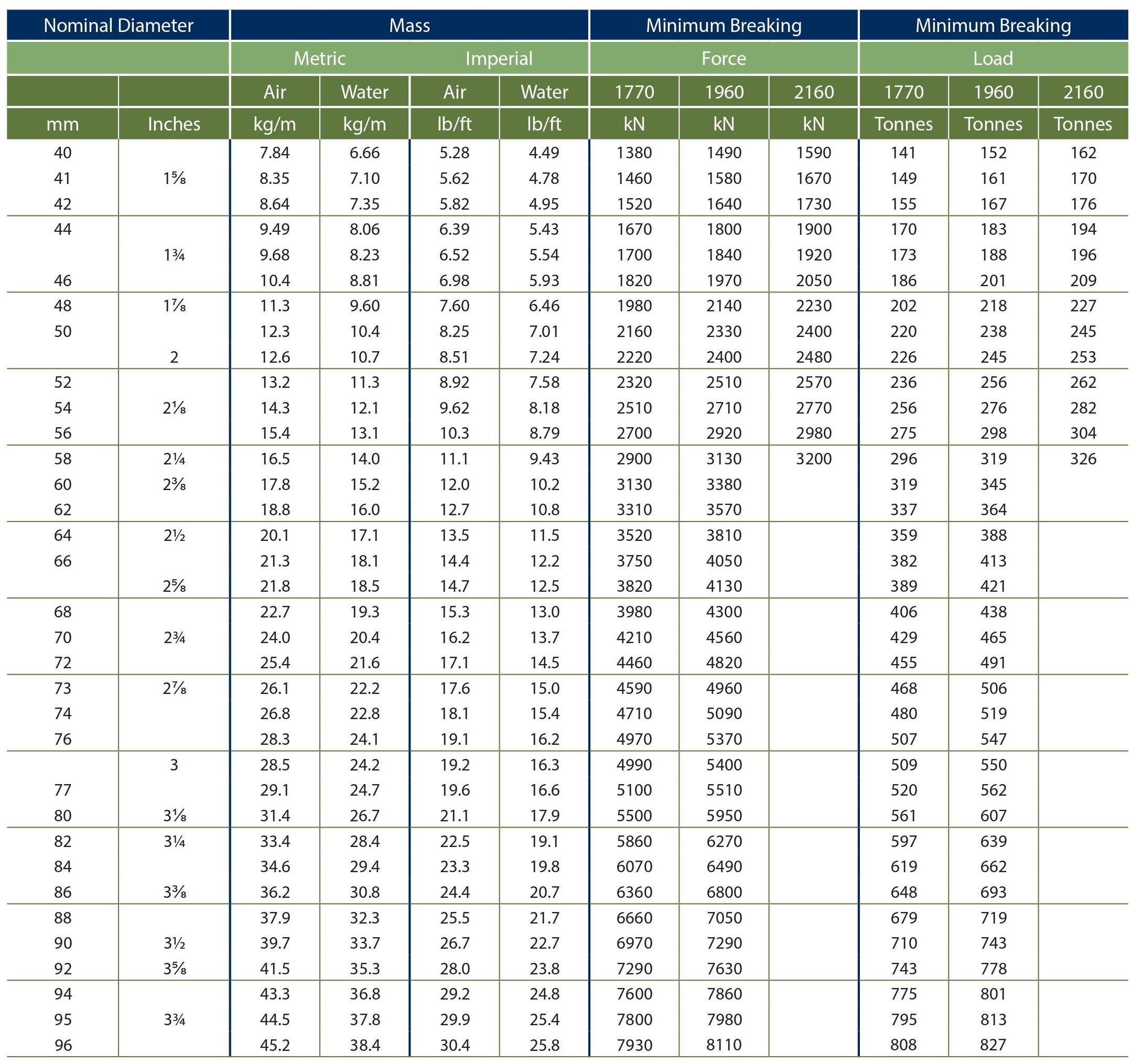

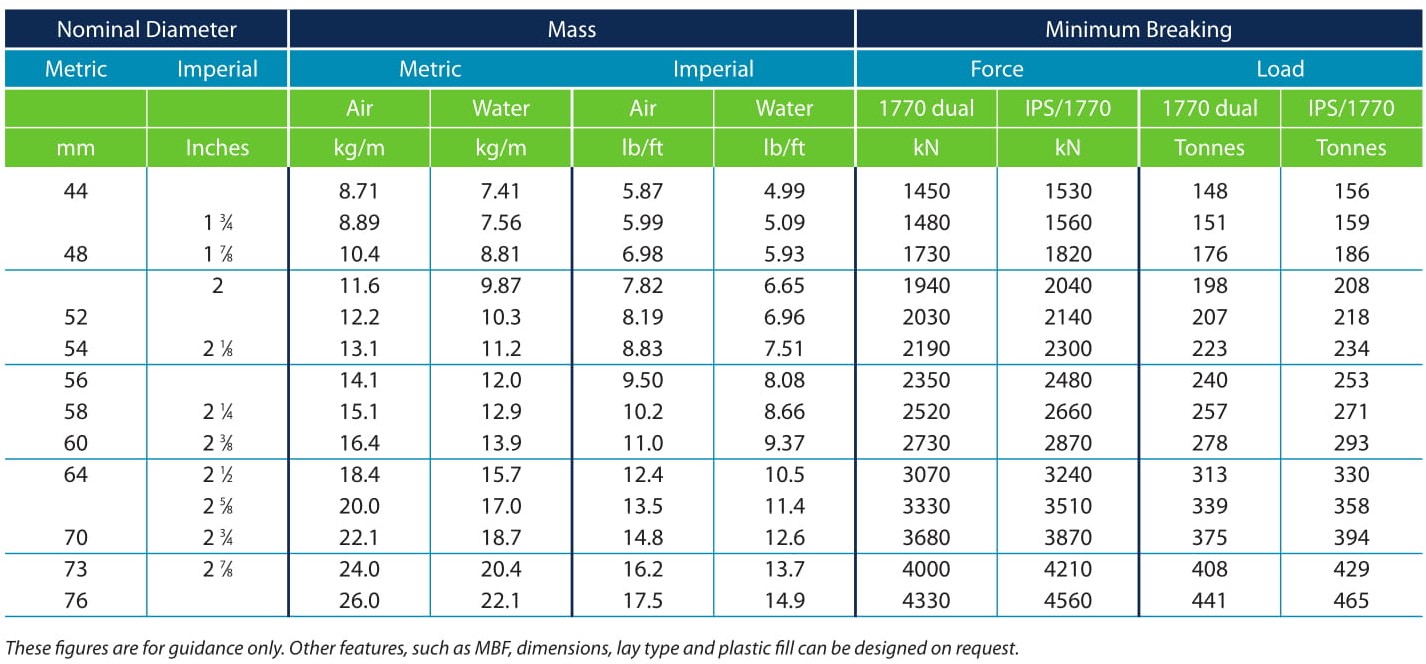

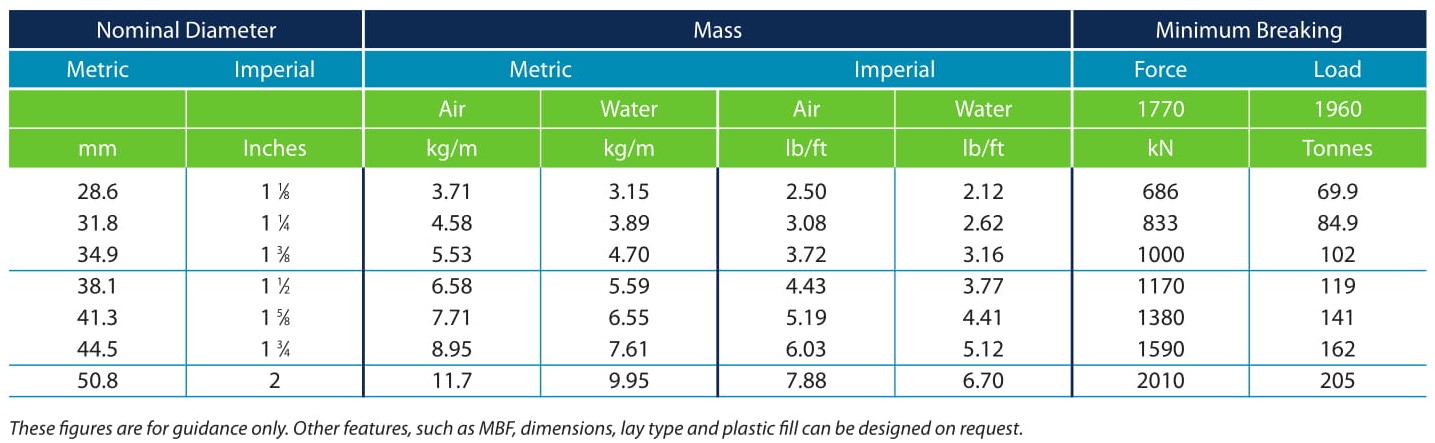

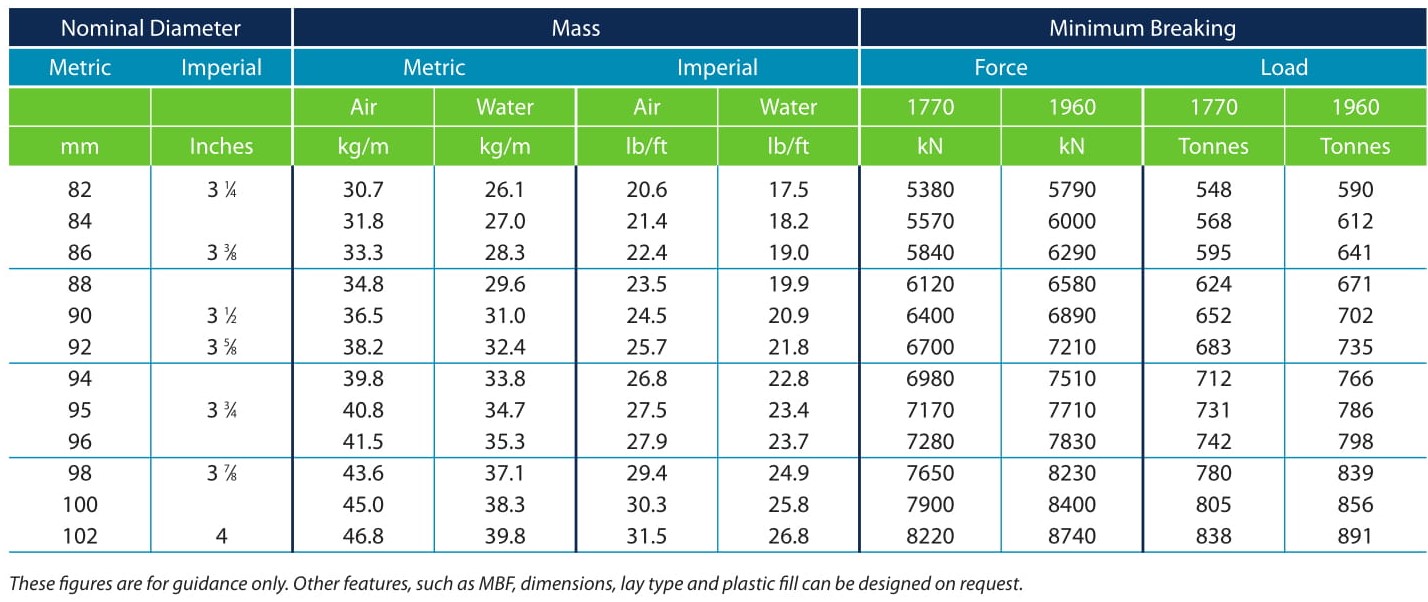

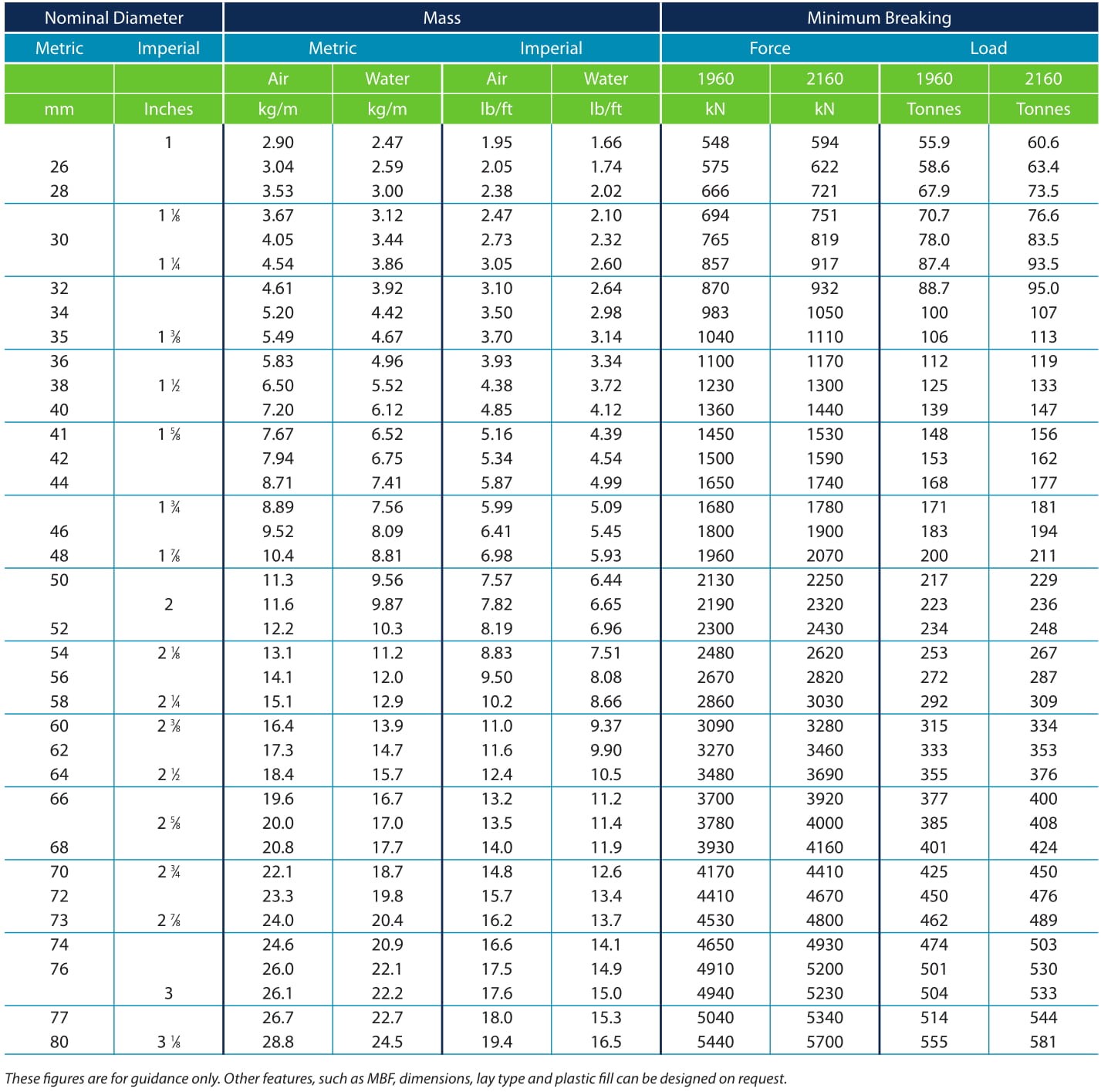

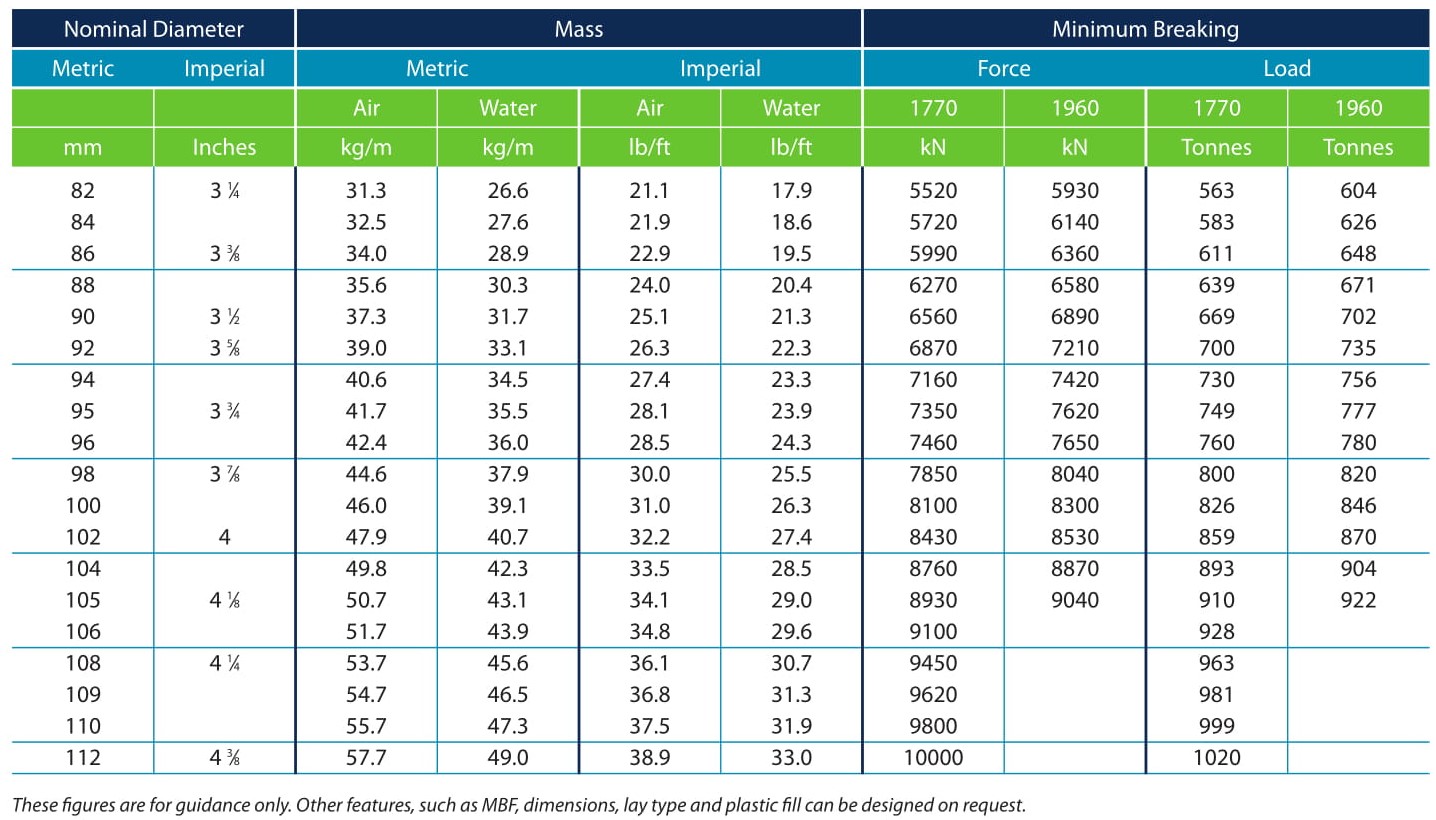

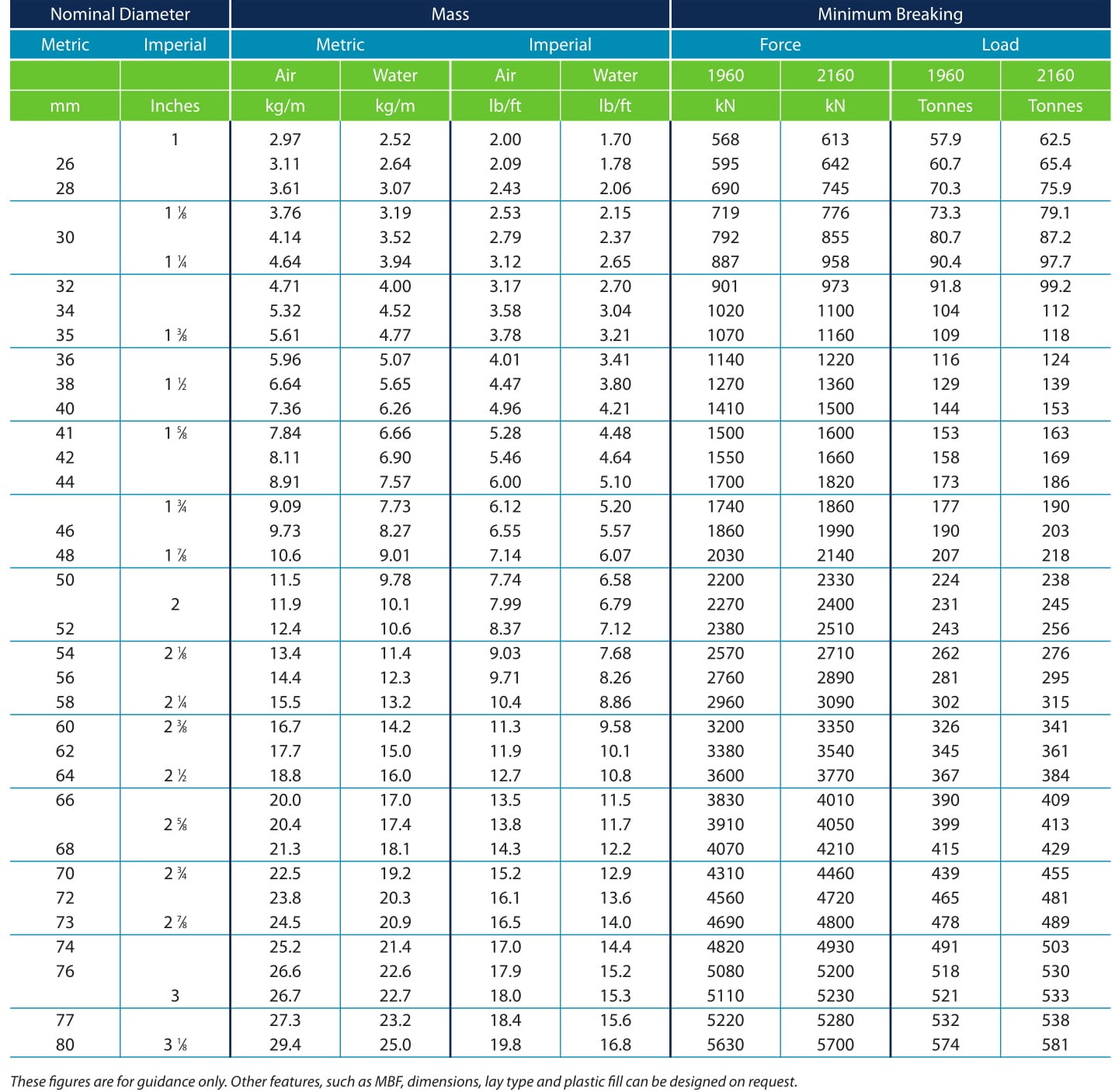

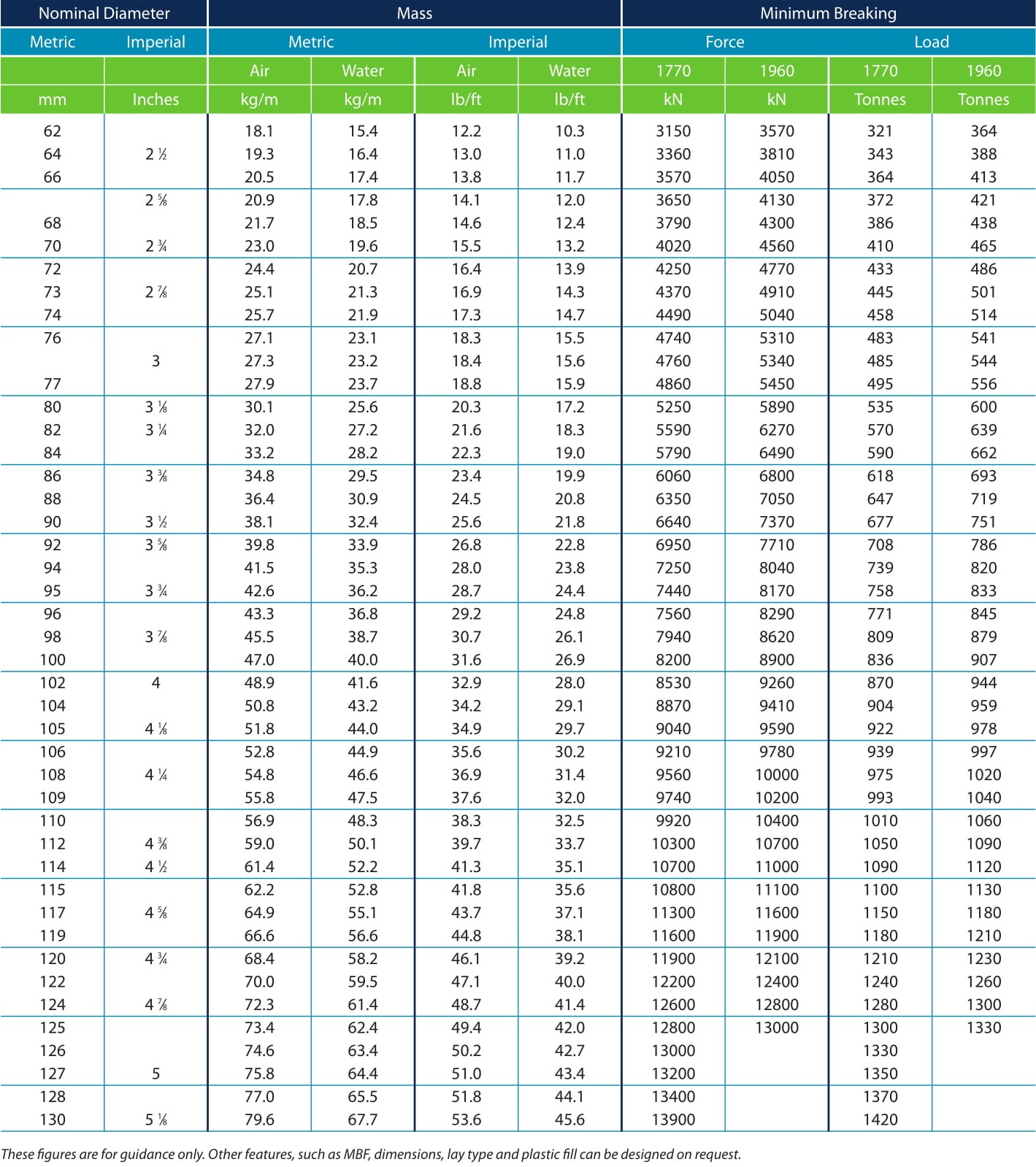

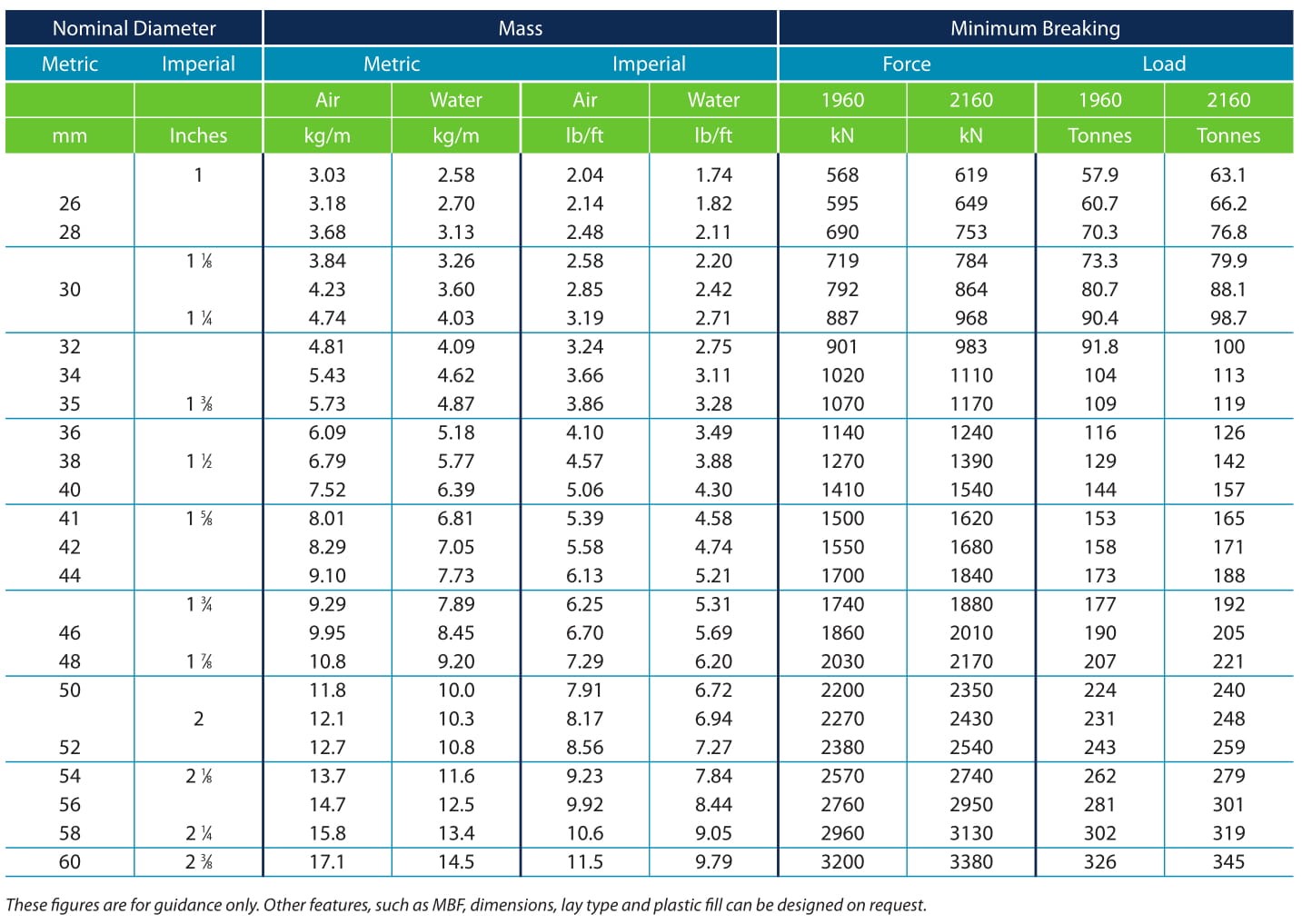

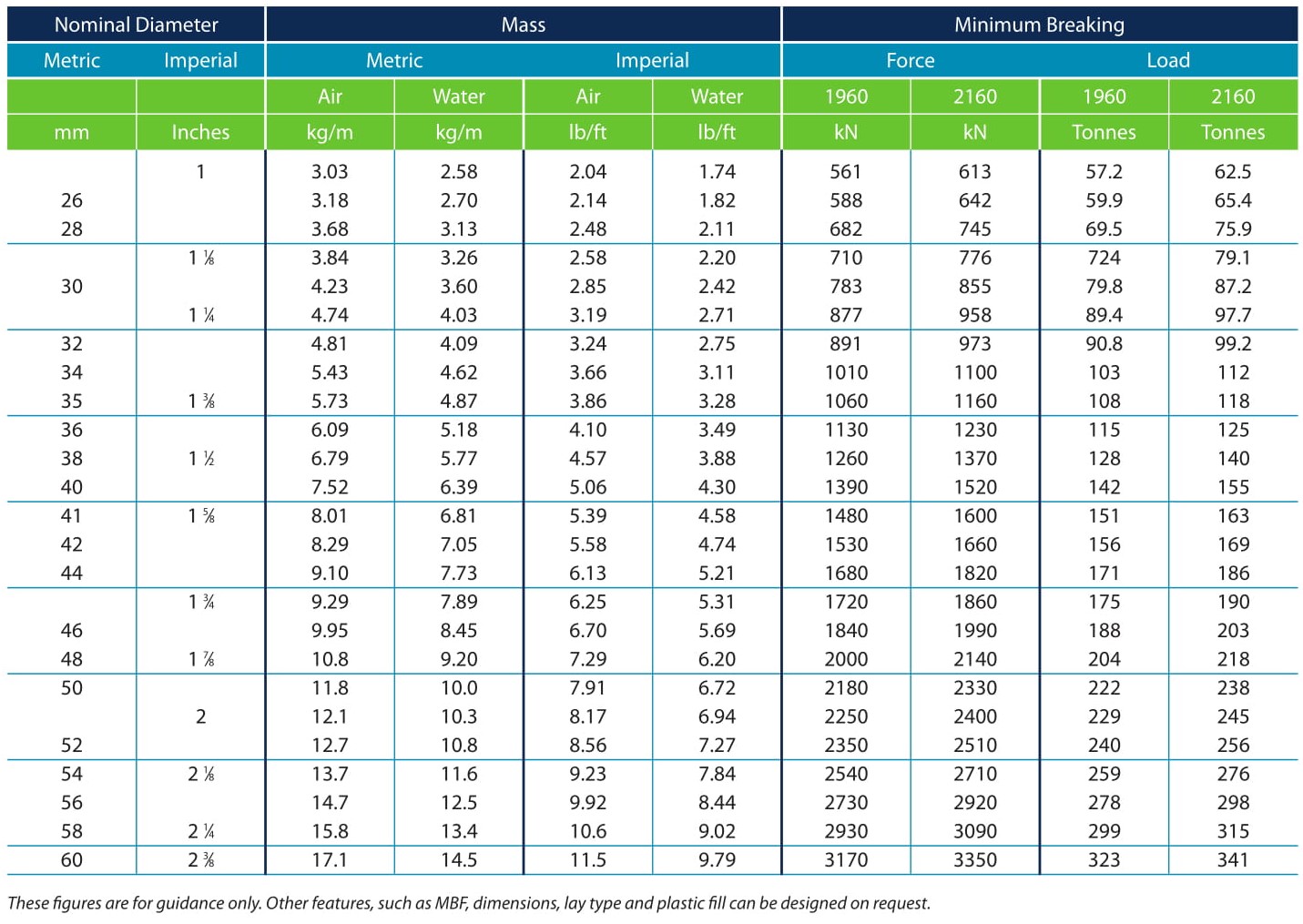

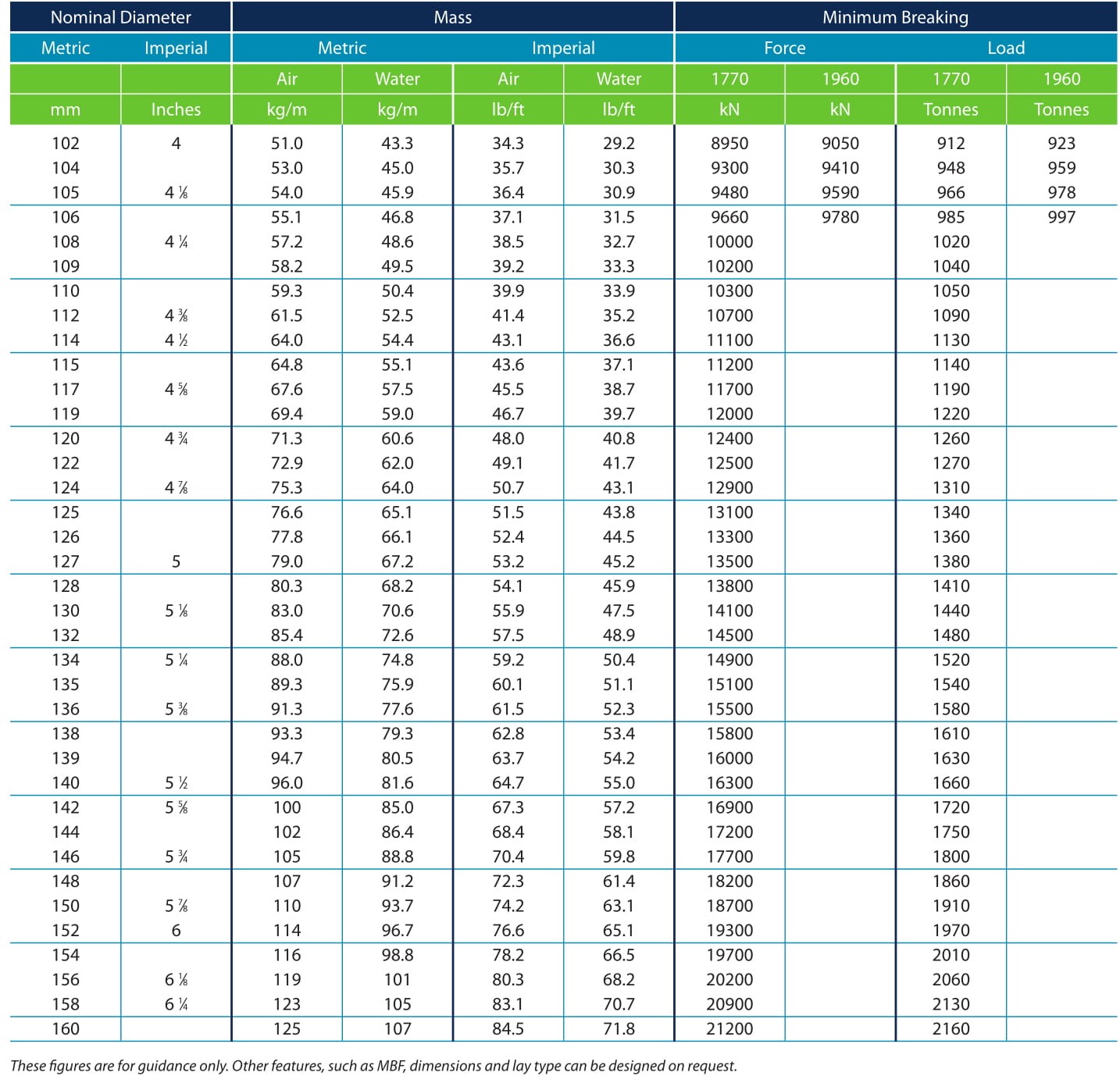

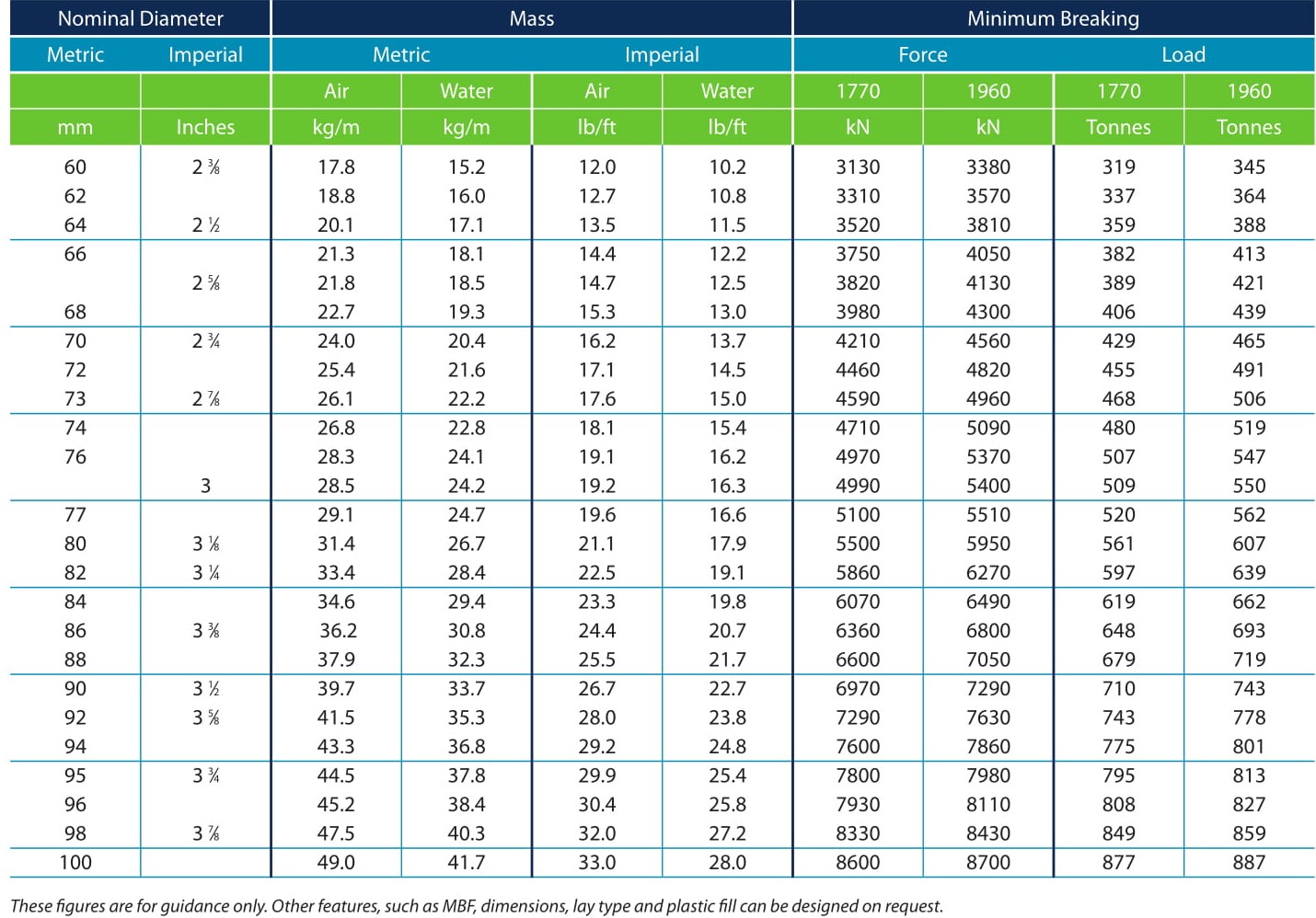

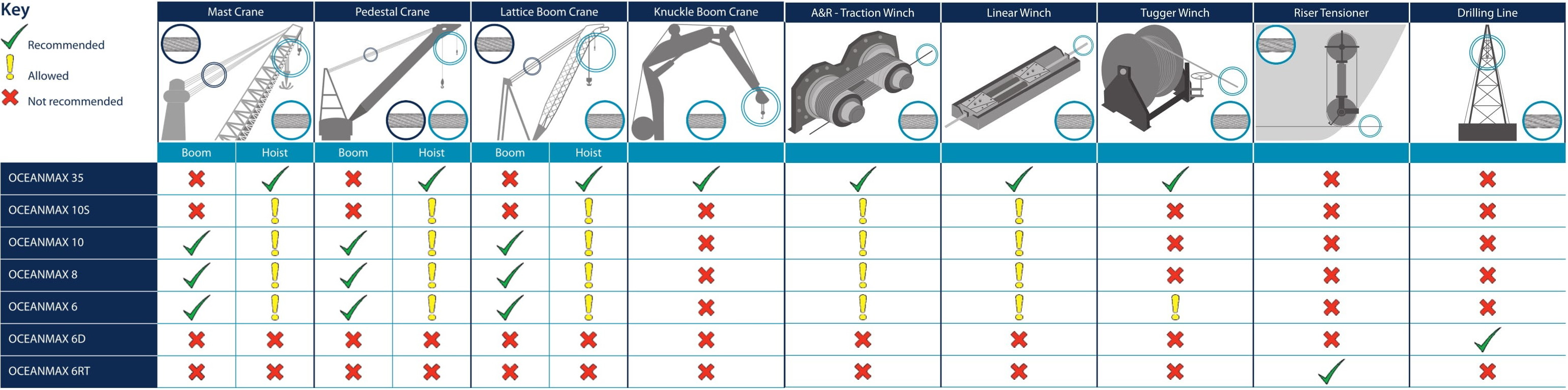

The OCEANMAX range of various rope types have individual characteristics which make them suited for one or more application. The detail in the table below should help engineers to determine the compatibility with the end use of the various ropes.

Brunton Shaw UK is a successful manufacturer of high quality, high performance compacted wire ropes which are designed to satisfy the technically demanding requirements of the Oil & Gas Exploration Industry.

The company effectively combines decades of experience and tradition with an up to the minute range of products and a customer service package ideal for the modern market place.

Brunton Shaw UK works in partnership with its customers, delivering quality assured, high performance products, backed by a commitment to service and continuous improvement. This dedication to serving customers has led to Brunton Shaw UK achieving sole supplier status with many of its partners and becoming approved suppliers to many internationally recognised companies.

To continuously meet the challenging demands of the Oil and Gas Industry, Brunton Shaw UK has developed the OCEANMAX range of compacted wire ropes.

Our determination to deliver quality products backed by quality service has meant continuous investment in both plant and people and this enables us to offer products which are fully tested and certified, produced through systems which are independently registered to BS EN ISO 9001.

In addition to our comprehensive range of wire rope and wire rope products, the majority of which are available from stock, we offer advice on rope handling, storage, installation, maintenance and lubrication.

“Strength in Service” is the proud claim of Brunton Shaw UK, a claim we are more than delighted to substantiate. We look forward to offering that strength and being of service, to all our customers.